Regulate with the Times

Ancillary material quality has become critical to the clinical advancement of cell and gene therapies. We need a regulatory framework that ensures safety, while also recognizing the growing cost burden on suppliers

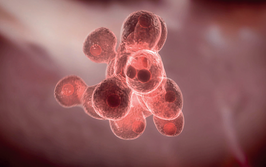

How can we manufacture cell and gene therapies in a safe and cost-effective manner to treat as many patients as possible? It’s the key question facing the cell and gene therapy industry right now. Ancillary materials are an increasingly important factor in the cost and safety of these new therapies. Unlike traditional small molecule medicines, cell and gene therapies cannot be sterilized before release. And that means companies must strictly qualify their ancillary materials as part of their effort to ensure patient safety, which comes with a substantial cost burden.

There is often variability among ancillary materials, which complicates efforts aimed at product characterization, specification, and quality management. The variability is largely due to the fact that, traditionally, ancillary materials were used primarily in a research environment, where requirements for material consistency, traceability and reliability are not particularly high. As therapeutic options have matured and moved to the clinic, these materials are now being placed under greater scrutiny by regulators.

Though there are several independent frameworks or guidelines that manage the quality of ancillary materials (examples include a Technical ISO Document led by the Standard Coordinated Body (SCB) with the participation of Japan, the UK, Germany and the US, among others, as well as the guidance set forth in USP Chapter <1043>), there is no official regulatory oversight. As a result, ancillary materials are produced according to different interpretations of “manufactured under GMP.”

Regulators recognize the importance of ancillary materials to the safety of the final product, and so they are quite stringent in their recommendations for which raw materials ATMP manufacturers should use. For example, the raw materials used in cell and gene therapies are complex in and of themselves – some are even pharmaceutical products, such as Interleukin 2 (aldesleukin). Regulators say that if you can use a pharmaceutical product instead of a reagent, then you should do so. But this means involving physicians and pharmacies, which creates a more complex supply chain, and further drives up costs. Another example is Human Serum Albumin (HSA). Regulators will often ask for injectable-grade HSA, even when it is only used in the manufacturing process (i.e. not as an excipient of the finished product) – again, increasing costs.

We need a way to balance quality with cost of goods. In some cases, it may be preferable or necessary to use ancillary materials produced in compliance with GMPs, including pharma-grade materials. However, developers may be able to control manufacturing costs without undermining safety or regulatory compliance in the case that a material presents a lower risk profile. Greater clarity and harmonization is needed to create a shared understanding of what constitutes a risk-based approach to ancillary material production and sourcing. The ISO technical document was a good start, but we need to go one step further.

My colleague, Oliver Ball, and I recently set out a framework for how we might go about regulating ATMP ancillary materials (1). In our article recently published in Cytotherapy, we propose a staged approach to ancillary material quality that progresses according to the user’s quality requirements (for example, throughout clinical development phases), implementing additional aspects of GMP compliance and a greater degree of control at each stage.

To briefly summarize, the framework is divided into three main stages: Development, Engineering, and Conformance. Ancillary materials produced under the first stage of development should be supplied for research use only – their manufacturing processes are in early stages of development, based on prior technical knowledge and pre-existing development work, and operate on a small scale. Moving into the second stage (engineering), manufacturing processes will be better optimized, with SOPs in place from previous experience in undertaking development runs, and a few changes will be made (although still acceptable in-process or between batches). Finally, the third stage of ancillary material quality represents close compliance to GMP principles and would usually operate on a larger scale. SOPs developed from the experience of performing engineering runs would be fully established and implemented.

Our belief is that suppliers will welcome this kind of approach because it relieves their pressure to invest in quality early – instead, they can invest progressively as the market expands. In other words, as manufacturers grow and move through the clinical stages, suppliers will invest in the quality of their ancillary materials in tandem. When a cell and gene therapy manufacturer begins discussions with regulators, the regulators will know that the supplier is working towards GMP and has documentation to support that.

We are currently in discussions with industry bodies to see if there’s a way to create a webinar or white paper to further develop this staged approach to GMP ancillary materilas. Our aim is to kickstart a discussion. Does our framework make sense to the rest of the industry? If so, great, but how can we make it a reality? If not, then what can we do to improve it?

The existing guidelines developed by the ISO and others have worked well, but I believe the industry has matured, which means the regulation must also mature. Our hope is that our proposal will provide a starting point for the development of a regulatory framework that recognizes the important downstream effects ancillary materials have on therapies that cannot be sterilized, while remaining attentive to the commercial realities facing this emergent industry.

- O Ball and C Zylberberg, Towards a common framework for defining ancillary material quality across the development spectrum, Cytotherapy, 21, 1234–1245 (2019).