Hopping Aboard the Darjeeling Limited

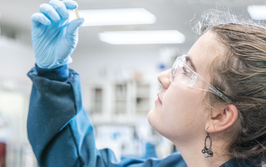

India has held pharma’s interest for decades, but now – more than ever before – there is great interest in setting up regional facilities.

Dev Ohri |

India is a fascinating place when it comes to healthcare and drug development. The country has a large population and a high population density, which contributes to the prevalence of infectious diseases. Add to that inconsistent levels of economic development, and access to effective and affordable healthcare becomes a huge challenge – a challenge that has triggered Indian companies to create cost-based innovations. Generic drugs in India are some of the least expensive in the world and the country is the second largest supplier of generic drugs by value, and the largest supplier by volume. Generic drugs in India include a broad range of small-molecule drugs, over-the-counter products, AIDS antiretrovirals, oncology drugs and more.

One of the largest disadvantages of drug manufacture in India is consistency and quality. Multinational companies with facilities in India usually keep to global quality standards, with integrated global supply chains and global management overview. But this is not the case for the entire market in India – I estimate that around 10 percent of the industry follows global quality norms and the remaining 90 percent does not. However, regulations are now tightening with major regulatory agencies, such as the US FDA and UK MHRA, pushing for stricter norms for pharma companies not only in terms of manufacturing practices, but also where they source their ingredients or components. Manufacturers of both small- and large-molecule drugs are being driven to partner with more reputable suppliers, rather than simply looking solely at price, which also pushes other suppliers in the region to migrate to higher standards to be competitive. Many Indian companies are improving in this area, but I believe there is still a need for global expertise to aid the transition.

Another important and notable trend in India is the increasing development of large-molecule drugs, and especially generics as more innovative drug products come off patent. Generic small-molecule products are becoming commoditized, leading to increased pressure on profit margins. Only a small fraction of pharma companies in India are investing in research and development, so the “copycat” industry will have a natural lifecycle, especially as it’s not easy to copy biologic medicines. Over time, I believe that the differentiating factors for these largely commoditized products in India will be the quality of materials they purchase and produce, and their production processes.

Finally, supply chain reliability is a challenge in India – as well as the majority of Asia Pacific for that matter. The size of the region is vast and the market is growing exponentially. Suppliers to the pharma industry, in particular, are under pressure to get their products to pharma companies quickly – and to this end there is a trend to establish regional facilities. The same is true for pharma manufacturers. In many cases, patients and governments are demanding local production capacity, but establishing a footprint in a new region is certainly not easy and can be very expensive.

Recently, I was involved in developing a new facility in Panoli, India, for producing pharmaceutical chemicals. I’d like to share some of the lessons I learned along the way.

A regional base

In today’s globalized industry, I believe that regional facilities are crucial for suppliers because they can reduce the supply chain from months to weeks. Many manufacturers in India or other emerging markets have highly dynamic demands, so if you have a supply chain with a few months’ lag, you may find that needs change before you can adapt to them.

Regional facilities are also great for the local community. Once one multinational company has set up a quality facility then others usually have the confidence to follow. In time, a manufacturing and quality hub appears, creating jobs and local benefits for the community – as well as raising standards throughout the region. Panoli is located in the highly-industrialized state of Gujarat; there are about 5000 different kinds of factories nearby and a major international port is only 70 kilometres away. But standards of safety in the area haven’t always been consistent.

Our Panoli facility has become a benchmark in the region and the Indian FDA sends representatives from other plants to look at our facility as an example of how to do things. Two years ago, we were awarded the National Safety Award for our plant operations. A quality plant creates awareness and boosts competition for business – and the best local talent. It seems all boats really are lifted by a higher tide!

The story of the plant goes back nearly 30 years. It started when Ranbaxy created an excipients capability called Ranbaxy Fine Chemicals, with the aim of developing expertise in both excipients and lab-grade materials. The Panoli plant was going to manufacture both lab- and pharma-grade materials, but we (Avantor) acquired Ranbaxy Fine Chemicals in 2011, when the facility was still under construction. We did not want two product lines with different standards of quality being manufactured under the same roof, so all the laboratory-grade and lower-quality requirement products moved out. At the same time, global teams moved in to make sure that the quality and design standards were up to scratch – and it involved a complete redesign of the facility.

When redesigning any facility, the biggest challenge is almost always dealing with existing infrastructure – the challenges (and costs) of retrofitting are well known in the industry. In our case, we already had employees working on some production lines and wanted to keep the retrofit going while also ensuring worker safety. I am very proud to say that, up to today, there have been zero accidents at the plant (touch wood!). Those of you who have worked in different markets will understand how rare this is, especially in an ecosystem like India, which can seem chaotic when compared with developed countries. There’s no big secret to this – don’t cut corners, and make sure your design teams have both local and global capabilities. I recommend hiring people who have worked for multinational big pharma companies with a good understanding of global standards of quality and safety. Throughout the redesign, you must maintain discipline and high standards.

Finding the right people in India can be perceived as a challenge, but given the country’s expanding pharmaceutical market and the number of multinational pharma companies in the country, there are many employees with excellent design, engineering and technical talent. Initially, when the Panoli plant was manufacturing both lab- and pharma-grade products, there were a lot of laboratory product packing operations, which led to a floating population of contract workers. Once we removed the lab-grade work, we found that the talents and skills of people who wanted to join us – and their engagement levels – increased, especially after we’d invested in the high purity, low endotoxin sugar wing of the facility.

Working to increase standards does often result in some involuntary exits – simply because not everyone in India is comfortable with the high, rigorous standards demanded in pharma manufacturing and pharma ingredients. Today, I think our attrition rate is a shade below the market norm. In growing economies, such as India, there are multiple options for talented, skilled employees – and you have to be prepared for poaching, especially once workers have experience in a quality facility.

Unexpected disruptions

When retrofitting, it is easy to overshoot your budget and it should be something you are prepared for (within reason) – holding onto a high-quality ecosystem in an environment that could easily be lower quality will always confer a competitive advantage.

Sometimes, you will face unexpected challenges. In one part of our Panoli facility, for example, workers were using mechanical excavators and drilling equipment, which was causing errors in the highly sensitive, quality testing equipment in a neighboring part of the plant. We didn’t want to risk compromising our data so we had to make some changes to the work schedule by resorting to manual labor, which increased construction timelines by more than a month. But it meant no vibrations and the rest of the plant ran smoothly – and the construction team did a great job.

Data integrity was a whole different challenge, largely driven by the perception that manufacturers in China and India sometimes fudge data or take shortcuts, which also causes a negative halo affect across the whole emerging market business. For this reason, I recommend getting an international consultant to perform an audit – that’s what we did to ensure that we were on the right side of the line.

As we are in the excipients segment, the US FDA has the right to audit our plants, but may choose not to because excipients (unlike APIs) are not on the FDA’s core list. The Indian FDA, however, has multiple rules around manufacturing, processing, quality, and the establishment of plants – and they are extra, extra strict when it comes to multinational companies! This is partly because there is a perception – and a legacy among countries that came from colonial rule – that overseas players may take advantage of the local population by exploiting worker safety, for example. In my experience though, if you adhere to the right standards and obtain the right licenses, then the Indian FDA is very supportive.

The global picture

When looking to establish a regional facility in India – or any other emerging region – my advice is to consider it a “global” facility with global standards from the very start. You may be tempted to take a shortcut and create a local facility similar to other nearby players, but you will quickly find yourself crowded out of the market. In addition, aim for “right first time” rather than trying to change things half way through. We experienced a number of delays and inefficiencies when we changed the design of the Panoli facility in 2011. Sometimes a change in design is inevitable (as it was in our case), but it is better to avoid it if possible. Also, draw upon the experiences and expertise of employees from your other facilities. Most plants have made mistakes at some point and have learned to refine processes. And I personally think it is incredibly rewarding to see a global company working together on project with standards shared across all geographies – a positive side effect!

You will need to ensure that you take into account the nuances of the local environment. For example, if you import machinery from countries of low humidity to more humid environments, then you’ll find that those machines will need some time adjustment. Employees with local experience, as well as experience in quality plants, can help with achieving the optimal levels of adaptation; for example, we had one piece of equipment where the drying was problematic, but a locally-made design change solved the issue.

It is also very important to keep a close eye on logistics. Is the facility located in a place where it can link in with both the international supply chain and the domestic network? Some locations in India are well networked – others are not... Just following the tax subsidies and putting a plant in the middle of nowhere can cause frustration further down the line! Fortunately, Panoli is in Gujarat, which is perhaps the most developed state in the country. It’s also well positioned between the Middle East, Africa and Asia-Pacific.

For suppliers, remember to engage with global customers immediately. When we inaugurated our facility, a number of customers were already aware of what we were doing, but initially we didn’t focus on forming an international identity for the facility. This is something we have now given a lot more direction, but I think there are benefits to looking at this early on.

Finally, don’t create an insulated facility. To create a facility that really packs a punch, bring in a blend of global and local talent, look to exceed rather than meet local standards, but be mindful to fit in with the community to make your plant the one that everyone wants to work at.

Dev Ohri is Executive Vice President, APAC, Avantor.

Dev Ohri is executive vice president, APAC, Avantor.