Plant Protein Potential

Can lettuce really help biopharmaceuticals turn over a new leaf? Researchers who have bioencapsulated blood-clotting factors inside salad leaves as a means to create affordable biologics certainly think so

Many biopharmaceuticals are far too expensive to be used by the majority of the world’s population. To that end, the search is on for cheaper and better ways of making drugs. And the answer could lie in plants. Henry Daniell, along with colleagues from the University of Pennsylvania School of Dental Medicine in the US, have demonstrated that it is possible to produce a protein drug bioencapsulated in lettuce leaves that can be taken orally by patients (1).

Using plants as an abundant source of medicine is certainly nothing new – mankind has been benefiting from nature’s arsenal since ancient times. In fact, plants are at the heart of Peter Seeberger and Andreas Seidel-Morgenstern’s low-cost antimalarials – work that received the 2015 Humanity in Science Award (2). However, the use of plant-based manufacturing platforms for biologics is a relatively new and exciting area. Daniell, who has been working in the field for some time, previously focused on tobacco plants, which are not suitable for human consumption. More recently, he turned to something more edible: lettuce.

We spoke to Daniell to find out how lettuce can potentially help with hemophilia.

You appear to be driven by the need for low-cost biopharmaceuticals...

Absolutely. Most protein drugs on the market today are not affordable for the vast majority (>90 percent) of the global population. One third of the global population earns less than $2 per day and the market capital of biotechnology companies was $1.25 trillion in 2014. The sale of protein drugs, which equated to $130 billion in 2013 exceeds the GDP of most countries. Insulin is necessary for treating the global diabetes epidemic and has been around for over 50 years. But we don’t do R&D for insulin anymore even though it remains so expensive that most of the world’s population can’t afford it. I wanted to do something about this and develop a way of making protein drugs more affordable.

The current production costs of protein drugs are mainly dictated by the operation and daily maintenance of sterile fermentation facilities that cost hundreds of millions of dollars. With traditional biopharmaceutical manufacturing, you also need to purify host cells using columns (which also costs millions of dollars), and then you need a reliable cold chain for storage and transportation. Most biopharmaceuticals also require sterile injectable delivery and also have a relatively short shelf life. Plants can help to eliminate these costs. Protein drugs made in plants can be stored in lyophilized cells and orally delivered without the need for purification, cold chain or sterile injections.

Could you share some examples of your work?

I’ve demonstrated that plant-based biopharmaceuticals could potentially treat metabolic or genetic disorders, including diabetes, hypertension, retinopathy and Alzheimer’s disease (3-5). We also recently received the top paper award from the American Heart Association for oral delivery of angiotensin to prevent or treat pulmonary hypertension.

Recently, in collaboration with the Roland Herzog Lab in Florida, we focused on hemophilia. Some protein drugs produce toxic antibodies when they are injected because the immune system cannot tolerate them. For example, when hemophilia patients are injected with blood clotting factors they can develop inhibitory antibodies. It’s a problem that affects a large number of patients and there is no effective treatment to remove these inhibitors other than ITI (International Team for Implantology) protocols, which involves using excessive doses of clotting factors to saturate the immune system. Such a treatment costs more than $1 million per patient, which is clearly not viable for most of the world’s population.

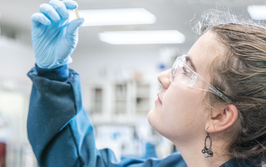

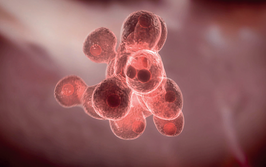

We have produced clotting factors in lettuce cells to teach the gut immune system to tolerate this drug. We introduce the therapeutic gene into the lettuce chloroplast genome using the gene gun; coagulation factor IX, or FIX is fused with cholera toxin B subunit to enhance delivery across the gut epithelium. The plants are then grown to maturity, and lyophilized and ground down. The freeze drying step is used to remove water and to protect the drug from any protease activity.

Blood clotting factors expressed in the plant cells (chloroplasts) are protected from acids and enzymes in the stomach because they are bioencapsulated within the plant cell wall. Gut microbes can then digest the plant cell wall and release the clotting factors in the gut lumen, where they are directed to the immune system by specific tags. This method facilitates development of tolerance to specific proteins. We’ve tested it with repeated injections of clotting factors.

Why lettuce?

Actually, we first developed this oral delivery system in tobacco cells, which are very easy to work with. We did a lot of experiments with mice, but the FDA would not approve protein drugs made in tobacco for oral delivery. So, we developed the lettuce system – and it works better than using tobacco. Our drug was efficacious across at least a 10-fold dose range, and there are also potential benefits in terms of shelf-life. Our work shows that lettuce cells can be stored at room temperature for up to two years, without any negative impact on the efficacy of blood clotting factor expressed.

What were the main challenges?

There were many! Achieving a high level expression of human blood proteins in plant cells was a major challenge and it took at least a decade to develop this system, first in tobacco and then in lettuce. Next, I had to develop a method to get proteins delivered across the gut epithelium into the circulatory system or immune system. And we needed to resolve the challenges associated with delivering the right dose.

The method has been submitted for FDA approval. What are the next steps in your work?

The scale up of our work in a cGMP facility is discussed in our paper (1). I can’t disclose names of major pharma companies due to confidentiality agreements, but I can say that things are moving forward rapidly. Based on my experience, the FDA is eager to approve safe and affordable protein drugs and I’m excited by the future prospects.

I am also eager to use this technology to develop vaccines against infectious diseases. The Bill and Melinda Gates Foundation is currently funding our research to develop a polio vaccine that doesn’t involve the use of live virus or a cold chain. Many problems are associated with the currently used oral polio vaccine (OPV), which is used in many developing countries that cannot afford the inactivated poliovirus vaccine (which is the one used in wealthier regions). We need to develop alternative methods to reduce dependence on OPVs.

What are your thoughts on the future of plant-based biopharmaceuticals?

Some drugs made using plant-based methods are already on the market. For example, two years ago the FDA approved a new treatment for Gaucher’s disease, a lysosomal storage disorder caused by mutations in the gene encoding glucocerebrosidase (GCD). The treatment is an enzyme replacement therapy using recombinant GCD made in carrot cells. Purified protein is administered intravenously twice a month.

It is a major challenge to think outside the box and develop a new technology. For example, the IT revolution changed the way we communicate and this dramatically decreased the cost of communications. I’m sure many international scientists painfully recall the prohibitive cost of phone calls from the US to home countries (costing more than rent) two decades ago... Technological revolutions bring with them incredible benefits. It is now time for us to see a revolution in reducing the cost of protein drugs – and I really think we are well on way to the finish line to making this happen.

- J. Su et al., “Low cost industrial production of coagulation factor IX bioencapsulated in lettuce cells for oral tolerance induction in hemophilia B,” Biomaterials, 70, 84-93 (2015).

- R. Whitworth, “Finding Humanity in Science,” The Medicine Maker (June, 2015). http://tmm.txp.to/0615/humanity

- V. Shenoy et al., “Oral delivery of Angiotensin-converting enzyme 2 and Angiotensin-(1-7) bioencapsulated in plant cells attenuates pulmonary hypertension,” Hypertension 64(6), 1248-1259 (2014).

- N. Kohli et al., “Oral Delivery of Bioencapsulated Proteins Across Blood–Brain and Blood–Retinal Barriers,” Molecular Therapy 22(3), 535-546 (2014).

- Sherman et al., “Suppression of inhibitor formation against FVIII in a murine model of hemophilia A by oral delivery of antigens bioencapsulated in plant cells,” Blood 124(10) (2014).

Making great scientific magazines isn’t just about delivering knowledge and high quality content; it’s also about packaging these in the right words to ensure that someone is truly inspired by a topic. My passion is ensuring that our authors’ expertise is presented as a seamless and enjoyable reading experience, whether in print, in digital or on social media. I’ve spent fourteen years writing and editing features for scientific and manufacturing publications, and in making this content engaging and accessible without sacrificing its scientific integrity. There is nothing better than a magazine with great content that feels great to read.