A Smarter – and Synthetic – Workflow for Bioengineering

Can artificial approaches trump the conventions of traditional organic synthesis for the production of raw pharmaceutical products within cells?

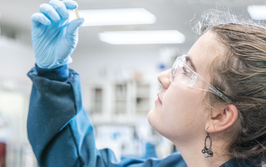

Researchers at Japan’s Kobe University have developed an integrated synthetic biology system that supports a more environmentally friendly approach to the synthesis of raw pharmaceutical products within microbes. Using a Design, Build, Test, Learn (DBTL) workflow (a pipeline for the discovery and optimization of biosynthetic pathways), the team constructed novel metabolic pathways and enzymes within cells that could be systematically optimized for the production of larger volumes of pharmaceutically relevant compounds (1).

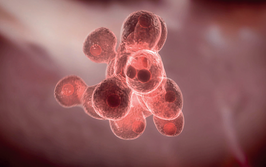

The project was carried out in collaboration with NEDO, a Japanese organization that funds many green research projects focusing on energy and industrial development. The Kobe group is leading NEDO’s Smart Cell Project, with a goal of developing adaptable cell factories for the production of diverse industrial materials. Using biological systems to produce industrial chemicals is more sustainable when compared to traditional chemical processes, but the current range of possible bioproduction targets is limited by known enzyme functions. Their recent report shows that it is possible to engineer new enzyme functions that can expand production capabilities towards new types of valuable chemicals.

“In this particular study we produced reticuline, a plant alkaloid and a key intermediate in the production of pain medications,” explains Christopher Vavricka, Assistant Professor in the laboratory of Tomohisa Hasunuma, a professor at Kobe University. “Previously, alkaloid intermediates like reticuline, and its precursor tetrahydropapaveroline (THP), have been produced using microbes and were unable to be produced at commercially viable levels.”

One barrier to large scale THP production is the relaxed specificity of monoamine oxidase (MAO) to the substrate dopamine. Using the predictive software, M-path, the Kobe team was able to identify an enzyme found in insects, which could bypass the issues associated with MAO. The researchers then used structure-based enzyme engineering methods to identify key amino acids in the silkworm enzyme, called 3,4-dihydoxyphenylacetaldehyde synthase (DHPAAS), and produce their own artificial DHPAAS, which could be used to improve production of the key alkaloid intermediate THP.

“We want to reach the point where we are able to produce reticuline at industrial levels; however, our current titers are still at the milligram per liter level. Therefore, we need to carry out more DBTL cycles with the goal of increasing production titers to the gram per liter level,” says Vavricka. The research team also wants to accelerate the entire process by increasing throughput and automation, but it may take some time to reach such a milestone. “Many experimental skills are an art that cannot be taught to machines any time soon,” adds Vavricka. “However, the handcrafted art of an experienced scientist is often slow and unpredictable. I hope the systematic and high-throughput approach of synthetic biology will speed up the development of applied biotechnology and help push science closer to its full potential.”

- CJ Vavricka et al, “Mechanism-based tuning of insect 3,4-dihydroxyphenylacetaldehyde synthase for synthetic bioproduction of benzylisoquinoline alkaloids”, Nature Communications, 10:2015 (2019).

After finishing my degree, I envisioned a career in science communications. However, life took an unexpected turn and I ended up teaching abroad. Though the experience was amazing and I learned a great deal from it, I jumped at the opportunity to work for Texere. I'm excited to see where this new journey takes me!