Formulating for the Perfect Tablet Finish

When it comes to film coating, there’s more than meets the eye. Is the drug or tablet core sensitive to acidity or moisture? What release profile is needed? And finally, how will the patient react to the finished product?

sponsored by Colorcon

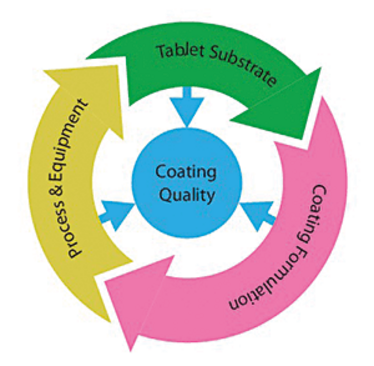

If you ask a consumer how they’d like to take their medicine or nutritional supplement, the chances are that they will pick a coated tablet over an injectable, liquid, or even a capsule. Coated tablets look familiar, are easy to handle and simple to consume. From the manufacturer’s perspective, coated tablets facilitate branding and market differentiation, but also offer the potential to incorporate functional attributes for dose delivery. Selecting the right coating, however, can be surprisingly tricky. And getting it ‘wrong’ can impact patient compliance or even compromise drug efficacy by negatively affecting the release profile. At the start of any project, you need to consider factors such as taste masking, swallowability, desired release profile, regulations for the intended market – and aesthetic appearance.

Form and functionality

The choice of coating depends on the chemical properties and chemical nature of the tablet’s core ingredients, including the drug or where it needs to be released in the body, sensitivity to the environment, and the physical properties of the drug’s active pharmaceutical ingredient (API). Every drug is different so there is not a “one-size-fits-all” coating. That said, there are few core formulations, such as some orally disintegrating tablets, that currently may not be able to be coated – it is just a matter of understanding the properties of the tablet core formulation and matching the coating to it.

Enteric protection

From a functional aspect, an important consideration is whether a tablet requires protection from the acidic environment of the stomach – or indeed whether the stomach requires protection from the API. In either case, an enteric (or pH dependent coating) will be necessary. Aspirin (acetylalicylic acid) is perhaps the largest marketed drug that includes an enteric coating, but second on the list are proton pump inhibitors (PPIs), such as omeprazole, (prescriptions for which continue to soar). For patients taking PPIs, acid secretion in the stomach is inhibited, which makes the stomach pH increase. As most enteric polymers dissolve at the higher pH (5.5) than found in the stomach (pH 1.2), the coating should be able to protect the PPI at intermediate pH levels (for example, the drug should be protected even at pH 4.5 acetate buffer). Our datasets show that Colorcon’s Acryl-EZE® II, an optimized aqueous acrylic enteric system, protects the drug at low and intermediate pH.

Moisture protection

Another common functional need of coating is moisture protection. Many APIs are poorly water soluble, so different technologies are used to enhance solubility; for example forming an amorphous drug from its crystalline (poorly soluble) form. These solubility improved drugs are moisture sensitive since they may convert back to their more thermodynamically stable crystalline form in the presence of moisture. Also, some drugs may degrade when interacting with moisture, so there is a lot of industry interest around moisture management for solid oral dosage forms. One raw material excipient that we generally recommend for a moisture sensitive core formulation is Starch 1500®, partially pregelatinized maize starch, which has excellent binding capacity with water and thus reduces the availability of moisture to the API.

Keeping Up With Coating Trends

Pediatrics & geriatrics

These specialized patient groups have unique requirements related to taste-masking and ability to swallow medicaitons. For pediatrics, manufacturers are looking to make sure their coatings are safe for use in children and it is advisable to look for products that use raw materials that have precedence-of-use for pediatrics. Meanwhile, the growing number of geriatric patients, with inherent polymedication, points to an increased need for product differentiation, as many such patients take multiple tablets.

Natural colors

Some industries, including food and pharmaceuticals, are facing growing demand, through consumers, for “natural” or “clean label” products. Natural colors are used in coatings but tend not to be as stable as synthetic pigments. The industry is working to address this, and a greater number of natural colors are now available. Spirulina extract has recently been FDA approved for wider use in coating formulations applied to dietary supplements, drug tablets and capsules marketed in the US, expanding the natural color palette available to the industry worldwide.

Regulations

Recent focus on medication errors has led the FDA to release guidelines to address tablet differentiation. Also, regulatory agencies are encouraging manufacturers to think more about patient compliance, facilitated by good tablet design and coating inclusion.

Continuous manufacturing

As the industry seriously considers a transition from batch to continuous manufacturing, there is a need for coatings that are compatible with continuous processes operating at higher speeds – without compromising final tablet appearance. We’ve been developing coatings that can be sprayed much faster and that have higher levels of solid in the coating dispersions, which significantly increases productivity while still delivering the perfect finish.

Coating formulation

We have also developed specific coating systems with moisture barrier properties, such as Opadry® amb II, a high performance moisture barrier film coating, which is a water soluble, pH independent dry powder film coating system for immediate release.

As soon as you know that your dosage is going to be formulated as a tablet, you should start thinking about which coating to include and begin working towards proof-of-concept in patients. It is well understood that many patients can’t easily swallow tablets and don’t like bad tasting formulations. Therefore the earlier you address these concerns, the better.

Connect with coating experts

When it comes to choosing and implementing the right film coating, don’t be afraid to reach out to others with the right expertise. There are many products available and even if your choice makes sense in theory, you may encounter problems with implementation at either scale-up or production if you’re not an expert in the area. Common areas for confusion include color and ingredient choice, as regulations for these vary by region and country across the globe. With expert insight, you’re much more likely to get your coating right first time. To start companies off on the right path, Colorcon can provide not only innovative coating systems and expertise, but also formulation insight through our HyperStart® service. This online tool is freely accessible to provide a starting core formulation, film coating, and process recommendations. It’s a great way to start the formulation and coating conversation and introduces important aspects related to development and processing early on.

Safety by design

The coating options available to pharma companies will continue to expand as new ways to improve the function and processing of tablets become available. As pharma moves towards continuous manufacturing, the process of coating will become faster and more efficient.

When you’re in this field, it’s easy to get caught up in the latest advances, but you should always remember to put the patient first. Without a high quality coating, tablets can erode or degrade in the bottle or packaging, stick to the throat, or leave a bad taste in the mouth. Even if a tablet doesn’t need additional protection from light, moisture or acidity, it should at least be suitable for the patient to handle and swallow.

Ali Rajabi-Siabhoomi is Vice President and Chief Scientific Officer at Colorcon.