Continuing the Trend

Continuous processing is being adopted in pharma and biopharma. Could continuous cell therapies be next?

Continuous manufacturing has been a growing trend in pharma for some time, but now researchers are urging cell therapy manufacturers to get in on the act. “Given the increase in the number and relative success of cell therapy clinical trials, treating a larger number of people is expected over the next decade,” says Che Connon, Professor of Tissue Engineering at Newcastle University, UK. “Cell manufacturing processes need to scale alongside this growth, as current systems won’t be able to meet the expected demand. For example, allogeneic heart failure therapy may require the manufacture of around 109 cells per dose. If existing batch processing can only enable lot sizes of 10–50 billion cells every two to three weeks, then the industry would require millions of batch bioreactors to be running simultaneously just to keep up with demand.”

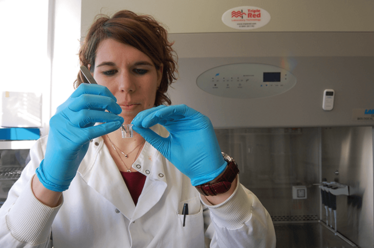

Currently, cellular therapies are produced by growing cells on a surface until no free space remains, at which point all the cells are detached and collected. The process is repeated for the next batch. Connon and his lab have been developing a continuous approach by coating the surface with a functional coating (lipopeptides) before seeding with cells (1). After the cells grow they “self-detach” from the lipopeptide coating, allowing other immature cells to take their place, so there is no need to chemically or enzymatically detach the whole batch. “A peptide sequence can be chosen to affect the function and stability of the lipopeptide, and we have shown that once self-assembled into a supramolecular structure, such material can form a stable coating upon a variety of surfaces,” says Connon. “Thus, it is possible to control the spatial and temporal positioning of cells across a surface if the lipopeptide contains a contiguous cell binding and endogenous protease cleavage site within the peptide sequence. In our new continuous bioprocessing approach, we tuned the system such that the rate of cell proliferation equalled endogenously-driven cell detachment by growing the cells on a rationally designed lipopeptide coating.”

Although Connon initially focused on human stromal cells, other types of adherent cells could also use the lipopeptide-based continuous approach.

Connon has demonstrated the approach’s ability to support continuous production for one month with no reduction in cell production rate. The cell yield is around one percent per hour. “Unlike traditional batch processing, yield is not a suitable comparator; the process is continuous so the number of cells produced is theoretically unlimited,” explains Connon. “However, the rate of cell production is limited to the surface area used. The greater the surface area, the less time it will require to generate a specific number of cells. For example, using current stacked plate technologies with our coating would provide one billion cells every week. A standard sized benchtop incubator filled with these plates could produce 5-10 billion cells per week – continuously.”

- M Miotto et al., “Developing a continuous bioprocessing approach to stromal cell manufacture”, ACS Appl Mater Interfaces 9, 41131–41142 (2017). PMID: 29145726.