Fighting Fakes

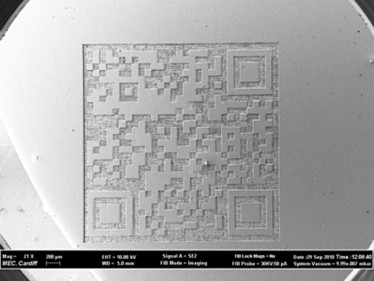

Initial bar code a “3D” QR type code

Track and trace is often used on pharmaceutical packaging but what if an invisible code could be applied directly to a tablet? In the UK, Phil Harrison has co-founded a company called Sofmat to do just that. The technology uses micro actuators to make tiny covert indentions directly into a tablet. These indentions can be used to give each tablet a unique number when scanned with a reader – much like the serialization code on a packet. We spoke with Harrison to find out more.

How did you get interested in counterfeit medicines?

Personally, I don’t believe enough is being done to tackle the problem of counterfeiting. And in some ways, counterfeiting has even become an accepted practice. For example, there are many people with fake Prada handbags or fake Rolex watches – these people know they are fake but it doesn’t matter to them. When these fakes fall to bits, people just buy new ones. A fake handbag or watch isn’t dangerous but some people also think that it’s OK to buy fake medicines, which come with more risks. Much of the emphasis on preventing counterfeits so far has focused on packaging rather than the actual goods themselves and that’s the drawback. If there was a marking on the actual product, then it could be very useful.

Professionally I’m a metallurgist and I’ve been doing that for over 40 years. In 2005, I ended up working for Huddersfield University, UK, in business development and in 2010 I was invited to a meeting about anticounterfeiting. Another attendee, Ben Whiteside, has expertise in micro moulding and we discussed the idea of making a 3D version of a barcode.

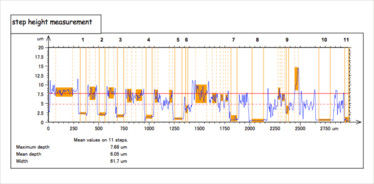

Linear trace across the centre line of the “3D” QR type code showing the step heights and the spacing of the indentations.

And a new company was born…

That was the starting point, yes! We obtained a little bit of funding to develop tooling that would make the initial code and at the same time we won a TSB proof-of-market grant. We used the money to develop sequential marking and to show that we could incorporate a lot of data in a tiny surface area. We also developed a reader and we’ve recently been awarded a prototype grant, which we’re using to get the technology closer to commercialization. Theoretically, we’re looking at April 2017 to have something on the market.

The company name is Sofmat. We sometimes tell people that it stands for the ‘security of materials’ but it actually stems from the names Sophia and Matthew: Ben’s daughter and my son. When we’ve talked about the technology that we’ve developed, we’ve had a lot of attention from Switzerland so that’s the market we’ve concentrated on. We’ve been working on the technology with the University of Bradford (UK) but we are not a university spin out.

The image above shows indentations in a simulated pill.

How does the technology work?

It’s a marking technique that uses micro actuators within a mould. The micro actuators can be pre-programed or individually programed and the indentions they make are approximately 0.5 mm in diameter and up to around 40 microns deep – and always in the same place on every tablet. You can’t see or feel the indentions without using a special reader. It took us about 8 months to develop the code so that it could be reproduced and used sequentially. We are working on several methods of measuring the indentations to ensure that we can cover a number of different market sectors.

We’re pursuing the technology’s potential for marking pills – we’ve mainly been working on polymer slow-release pills. But it can also be used in other applications too, such as for marking metals and plastics. We’re also looking at using it to mark vials, such as Botox vials or caps. The technology is pretty easy to implement – it fits within existing moulds and it’s relatively low cost.

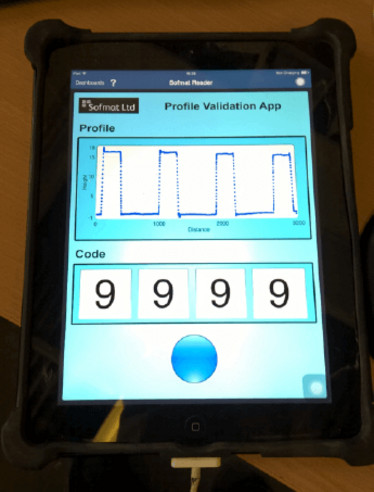

The image above shows the “decoding” of the image to produce a alphanumeric signal.

How will it fit into real-world supply chains?

We’ve designed the indentations sequence to match the track and trace activities currently used in the industry. Our code will tell us who manufactured the tablet, which pack the tablet has come from, and then the tablet itself will also have a unique number. If a tablet with the same number has already been used elsewhere then you know you have a fake product somewhere.

How does it compare with other anticounterfeiting technologies?

There are lots of different anticounterfeiting technologies out there and some of them can also be directly applied to tablets like ours. Some companies have put tracers on tablets but this requires FDA approval. Our technology does not alter or adulterate the tablet at all so you don’t need that sort of approval.