Getting Under the Skin of Extractables and Leachables

There are key benefits to having an industry standard for E&L studies – but a standard is only the beginning. The bigger question is what comes next and how do we dig even deeper into single- use systems?

sponsored by GE Healthcare

As Strategic Projects Leader at GE Healthcare, and first Vice Chair on the executive board of the Bio-Process Systems Alliance (BPSA), Jeffrey Carter focuses on the world of single-use manufacturing. He facilitates collaboration, engages with industry stakeholders and fires up discussions to help solve the most critical problems facing users and suppliers of single-use systems.

One issue he has focused on recently is the industry’s growing uptake of single-use systems and what effect this will have on the way extractables and leachables (E&L) studies are performed.

What is your role at GE Healthcare?

I spend my time trying to identify and understand the most pressing global issues in adopting single-use systems in biomanufacturing – and then investigating how we can help resolve those problems, either within our company or as part of a broader, external industry collaboration.

Single-use technologies are certainly becoming better established, but there are still some issues that users and suppliers must consider, such as addressing particle presence, leak rates, change notifications, and managing the supply chain. One of the most talked about issues is the potential for leachables from single-use material. These leachables could end up as contaminants in drugs and lead to unwanted effects.

What global trends do you see in today’s biopharma industry?

Despite the relative youth of the biopharma industry, certain (sometimes inefficient) practices have become engrained. Making drugs, especially specialty biopharmaceuticals, is a notoriously expensive business, and success in today’s fast-paced industry often involves bringing down your cost of goods, getting to market more quickly, and managing various forms of risk. To that end, people are trying to figure out how to move away from the ‘standard’ manufacturing practices (batch unit operations, stainless steel, glass...) and attempting to make their processes more efficient. Two important goals for the industry are to increase the speed and flexibility of manufacturing. Single-use technologies can help in both regards; they are not a silver bullet, but they are very effective at increasing flexibility and can be deployed very rapidly. Conversely, meeting changing needs with a hard-plumbed, stainless steel infrastructure can be difficult.

What does an increase in single-use technology mean in terms of E&L?

E&L is a well-known topic in the industry, as they are a staple tool to evaluate safety aspects to surfaces that are in contact with process fluids or final drug products. People have been talking about E&L for years – and they have been successful in managing it for the most part. That said, E&L have not always been managed in the most efficient way, particularly when it comes to creating datasets.

Today, we’re seeing greater uptake of single-use technologies, which means the amount of plastic in the manufacturing line is increasing. Historically in manufacturing, you perhaps had a sterilizing filter that needed E&L testing, which was relatively straightforward. Now, you might need E&L data for the sterilizing filter, in addition to a process bag, a tube set, connectors, and buffer bags. There is also the issue that material changes trigger a new extractables study, which adds to the volume of studies to be managed by both users and suppliers. When you double or quadruple volumes, inefficiencies in the current way of working quickly become apparent. One problem that is significantly adding to the burden is the lack of industry norms when it comes to extractables study designs.

At the moment, end users obtain extractables data from multiple suppliers. But each supplier has their own approach and analytics, so end-users end up with myriad data sets and consequently spend a lot of time, resources and money trying to draw conclusions. From their perspective, it is a frustrating exercise akin to comparing apples to oranges.

Is there enough knowledge in the industry about the importance of E&Ls?

Some people are fully engaged with E&L at a quality level; they understand that E&L study results have intrinsic value in assessing the quality of single-use equipment. Others see it as more of a compliance issue; the work must be done because it is a regulatory expectation, but they are not interested in the gritty details of study design. Others are even more tentative with E&L studies. Indeed, companies sometimes ask for our opinion on how to manage extractables and whether they should be conducting a leachables study. We can help these people by orienting them on how one might design a risk assessment and by providing technical information. Ultimately though, the conclusions and decisions that ensue must be owned by the end-user.

How is the industry moving towards standardized E&L studies?

An industry standard for E&L testing, which is being discussed by stakeholders at the moment, would allow everyone to at least read from the same instruction book. We would all know what the study design should look like, and how it’s supposed to be executed, meaning that the reports at the end should consequently look very similar. The data would be easier to manage and process, saving time and resources. In reality, a standard would not be a panacea, but it would be a very good start.

And you’ve been involved in the discussions?

I’m one of the voting members for ASTM’s Committee E55 on the Manufacture of Pharmaceutical Products. ASTM is a standards-setting organization, and though it’s not the only organization of its type, they do have a very rigorous process for developing and approving international consensus standards. I was on the original committee that was working between the BioPhorum Operations Group and the BPSA to work out a proposal that would be submitted to ASTM. Some of the questions being addressed are:

- what is the correct test article?

- what solvents should be used for the extractables test?

- how long should the extraction be conducted?

- what time points should be used?

- what should the analytics look like?

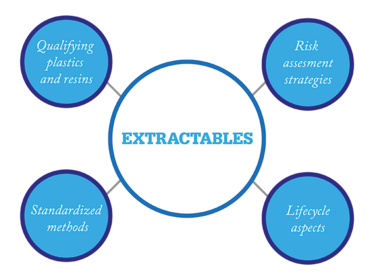

The big question: what comes after the standard?

It’s not clear if or when a standard will appear, but regardless, the standard is just one step. Other topics need to be discussed too. One concern for me is that whenever we test something, there is an element of “testing quality in”. In other words, we’re assessing whether or not the plastics being used are adequate for the task, but only after the plastic components have already been made. As an industry, we should also be looking to solidify standards that we use to qualify the plastic resins and additives in the first place. In my opinion, this is a good place to practice quality-by-design principles.

We also need to talk about how we use data. Once we have standard datasets, what do we do with them? Those that already know the answer to that question are fully primed to make best use of data. Other companies are not so prepared. When they receive extractables data, they will ask if this is all they need, or if they need to take the next step and execute a leachables study that is process-specific, rather than relying solely on the supplier’s intrinsically generic extractables study. The answer to this question is rooted in process- and product-specific risk assessments. To date, we have seen generalized industry guidance stating that various unit operations are typically seen as high, medium or low risk; however, I wonder if it would be beneficial for the industry to convene a working group to add detail and discuss how risk assessments are conducted.

Finally, we should talk about extractables studies in a lifecycle context. For example, when we consider changes to single-use products, under what circumstances does it make sense to re-do an extractables study? Some argue that in the absence of a change, there is no reason to arbitrarily re-do the study; others argue that processes drift over time and that it would be good practice to re-do the studies at some to-be-determined frequency. These questions are best addressed as an industry collaboration.

How else do you think single-use technology will affect the industry?

Clearly, technology is always evolving as suppliers improve the products they offer, but change management practices often prevent users from adopting intrinsically better, more robust, solutions. I am hopeful that we can strike a new balance that can open the change pathway. The concept of “functional equivalence” is one that the industry should explore. At GE, we don’t want to “force” changes on our customers; rather we want to share information about what options exist and by doing that help them to make well-informed decisions. The more insights we have and can share, the better the final outcome.

Single-use technology will also mean changes for the supply chain. Adopting single-use manufacturing means that the end-user will relinquish direct control over some quality attributes of their manufacturing equipment and become more dependent on the supply chain. This in turn leads to a need for more information flow from both up and down the supply chain, which will only happen when there is mutual trust. To this point, I think end-users are starting to grapple with the natural tension that exists between wanting to play suppliers off on each other to foster competition, and wanting to develop these more seamless partnerships that are key to managing quality in a single-use equipment environment. It is instructive to ask the following question as we all work our way through our new relationships with our suppliers: are we buying commodity items that can be replaced without skipping a beat, or are we developing security of supply?

The speed and flexibility advantages of single-use equipment are likely to continue to play out, and we will see how the industry adopts this technology on a more wholesale basis in commercial manufacturing, as opposed to process development and clinical batch production. The technology advances are likely to proceed more quickly than the strategies for managing the quality of the technologies and the control of the technologies to assure predictable and reliable performance. From this perspective, it is interesting to turn the question around and ask how the industry will affect single-use technology. I think the more advanced end-users will have a marked influence on not only the technologies that we develop, but also the control strategies that we adopt to support the technologies from a quality perspective.

Making great scientific magazines isn’t just about delivering knowledge and high quality content; it’s also about packaging these in the right words to ensure that someone is truly inspired by a topic. My passion is ensuring that our authors’ expertise is presented as a seamless and enjoyable reading experience, whether in print, in digital or on social media. I’ve spent fourteen years writing and editing features for scientific and manufacturing publications, and in making this content engaging and accessible without sacrificing its scientific integrity. There is nothing better than a magazine with great content that feels great to read.