Industrializing Cell Therapy

We know that cell therapies work; now, we need to learn to manufacture them efficiently on an industrial scale.

sponsored by GE Healthcare

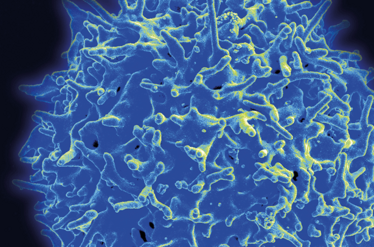

Many see the growth of the cell and gene therapy field as the culmination of a healthcare revolution – a move away from one-size-fits-all approaches to truly individualized and personalized treatments. Over the past few decades, increased understanding of immunology and genomics has generated an unprecedented amount of biological information, which scientists are now beginning to translate into a new calibre of medicine. It’s an especially exciting time for the field; the first two approved CAR-T therapies are already treating patients in the US and Europe.

“The complete response rates being seen for these kind of therapies are inspiring,” explains Madhusudan Peshwa, Ph.D., Chief Technology Officer, Cell Therapy business, at GE Healthcare. “I am not aware of any small molecule drug or any biological drug having the ability to deliver such phenomenal outcomes for patients. This is stimulating the growth of the cell and gene therapy industry.”

As the field continues to transition from the discovery stage to therapeutic reality, with further approvals sure to come, new challenges are emerging. The search for answers has quickly shifted from the mainly biological questions facing early-stage research scientists, to the challenges of industrializing and commercializing such therapies. “The industry is starting to realize that coming to grips with the manufacture of cell therapies involves a change in mindset and approach. With small-molecule drugs and biologics, manufacturers synthesize a batch of product in a “scale up” process, which often involves lyophilization, followed by conventional distribution and marketing,” says Phil Vanek, Ph.D., General Manager of GE Healthcare’s Cell Therapy Strategy. “Autologous cell therapies are different – for a start, they can’t be lyophilized or formulated as a traditional tablet! But most of all, they require manufacturers to take a “scale out” approach. Every patient needs their treatment to be manufactured individually, so if a manufacturer needs to produce 5000 patient batches, or doses, a year, they must run each batch in serially or in parallel.”

As the starting material for cell therapies is derived from patients themselves, Peshwa also points to another challenge: “There is a wide range of variability from person to person, in terms of the attributes and properties of the starting material, which makes it difficult to ensure that the manufacturing process always delivers within a defined range of attributes. We need manufacturing methods that can increase the reliability and consistency of the final product, no matter the starting material.”

Close and automate

Finding ways to remove risk from the process is one of the main focuses for cell therapy manufacturers. Cell therapies are a multi-step process involving collection of the material from the patient, transportation to the manufacturing site, manufacturing the product, and then shipping it back to the patient, but there are also dozens of other process steps in between – and when you are working with biological material and processing steps that require biological activity, the process does not discriminate between the cells of interest and bacterial contamination. The material must be treated carefully throughout – and the best way to prevent contamination is to automate a closed process.

“Historically, people have done whatever they needed in the clinical center to make these therapies happen, but given the expected growth of the cell therapy market, the industry will need to think more about an automated, industrial environment that can cope with larger patient numbers,” says Vanek. “Manufacturers will need to consider consistent manufacturing and product quality, utilization of space, operational effectiveness and cost efficiency. Use of data – via smart systems based on digital and analytical technology – will also be key as it will offer insights into controlling manufacturing processes and ensuring product quality consistency. In time, we’ll be able to use this knowledge to further automate processes, reduce the number of manufacturing steps and allow for aseptic transfers without manual interventions or a high degree of risk of exposure to the external environment.”

GE has developed a number of tools and techniques that can be used to automate and close the manufacturing process – most of which are based on established flexible bioprocessing technologies, such as single use systems, or WAVE™/Xuri™ bioreactors. The word “flexibility” is crucial when it comes to cell therapies. Right now, the industry is learning many lessons about developing and manufacturing these therapies – and knowledge will only increase. In a few years, it is likely that processes will be very different, so deploying flexible technologies now, which have the capability to be adapted in the future, is a wise precaution. “In the future, I expect that we’ll have much smarter methods to engineer our cells so that they are much more potent, which will change therapeutic doses and the amount of product that must be manufactured,” says Peshwa. Does this mean that companies should hold back on implementing new technology? Not at all – there are huge opportunities for cell therapies today, and first movers will certainly reap the benefits.

“And there are a lot of fantastic solutions already available,” says Vanek. “We’ve been approached by a number of customers looking to accelerate their path to market. They explain their basic process and then ask us to equip a factory for them. We’ve leveraged all of our experience gained with KUBioTM facility and our Enterprise Solutions to develop a solution for cell and gene therapies – it is basically a prepackaged factory ready to go.”

But for cell therapies to truly be mass manufactured, there is also a need to make processing steps less specialized so that they can be carried out by non-experts. Given the cutting-edge nature of these therapies, many of the processes are comprehensible only to the specific scientists and technicians who worked on them at the clinical stage – and this small number of experts will not be enough to scale a therapy to thousands of patients. “When we work with customers, we look at their processes and investigate whether any steps can be simplified into sub-routines or made more efficient by removing certain steps. We also look at trying to introduce new technologies or methods that can accomplish those sub-routines as opposed to thinking about all the unit operations independently,” says Vanek.

“Looking at the process workflow and identifying steps that have the highest risk, and then finding an effective way to automate these steps is a low-hanging fruit in terms of reducing the risk of contamination,” adds Peshwa. “Right now the industry relies heavily on aseptic process qualification operator training and environmental monitoring in being able to deliver an unautomated manual process – and certainly this has been a success – but automation would bring about a significant reduction in cost of goods and help make product quality more reliable. Every time a human performs a step in a complicated process, there is the potential for a mistake to be made.”

Finger on the pulse

Peshwa describes GE Healthcare as a company that likes to “keep its finger on the pulse”. Indeed, the company is always looking out for technologies in the marketplace that could lead to more effective ways of engineering cells, enhancing their potency, and assessing the biological attributes or “fingerprints” of a therapy. “But most of all, GE Healthcare is not just a vendor, but a value-added partner,” says Peshwa. “We work with customers to understand the product attributes that will drive clinical success and then we consult with customers through their stages to ensure they are optimizing their process. We’ll also make sure that requirements from a robustness and scalability perspective are addressed early on – this is incredibly important to ensure smooth scale up.”

Vanek adds, “GE has demonstrated real commitment to the field of personalized medicine and now is the time to move forward and help manufacturers overcome the challenges in the field. As an industry, we have more understanding of the causation and progression of cancer than we’ve ever had before, as well as developing a capability to effectively stratify patients in the future. Coupled with the genomics revolution, we are moving towards a whole new era of medicine.

Phil Vanek is Ph.D., General Manager of GE Healthcare’s Cell Therapy Strategy. Madhusan Peshwa is Ph.D., Chief Technology Officer, Cell Therapy business, at GE Healthcare.