Podifying Cleanroom Processes

With the advent of mobile, flexible cleanroom solutions that can be moved to wherever medicines are needed, are traditional cleanroom infrastructures about to become obsolete?

Containment is a key word in our industry and cleanrooms are an essential part of pharma manufacturing. As discussed in a previous issue of The Medicine Maker (1), the technology behind the modern day cleanroom dates back to the 1970s and there is doubt as to whether such static infrastructure is best suited for the needs of today’s industry, where flexibility is key. One of the main problems with traditional cleanrooms relates to scale up. Extending a cleanroom is a time-consuming and messy affair – and every time you scale up, you have to re-qualify the cleanroom infrastructure, which disrupts the manufacturing process. As soon as you start moving traditional gypsum walls, other problems can also become apparent. When speaking to peers in the industry, people have often said to me, “We opened up a cleanroom wall and found mold.” Contaminations like this are a hidden fact in the industry. Many cleanrooms are simply too outdated to fix – no matter how much money you throw at them. I don’t believe that cleanroom infrastructure should be a sunk cost. Many infrastructures are mothballed at the end of a product’s lifecycle because the investments would be too high to refurbish or modify the facility to meet the new processing criteria. This wouldn’t be a problem if we had autonomous, flexible cleanrooms that could either be repurposed for another application or transferred to another site – even another country.

Meet the “POD”

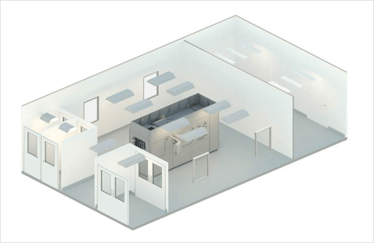

In 2011, I was introduced to the concept of independent, prefabricated cleanroom “PODs” that can be used inside of a facility in place of a traditional cleanroom. A modular and moveable cleanroom is not a unique concept as such – a number of companies have built container-based facilities that can be connected to a standard facility, but once interconnected these systems become just as inflexible as a traditional facility system. Pods and container-based cleanroom units differ mainly in the assembly – the pods are independent cleanroom units, which require a shell building, but container-based systems are interconnected units, which ultimately assemble to a free-standing facility.

The pods I was shown each had their own air-handling and control units, as well as fire suppression system. Like a normal cleanroom, there was a gowning area and a cleanroom area. Depending on the situation, the pods can be “docked” to corridors within an existing facility, be delivered with a corridor pod or have the corridor included in the pod structure. Importantly, the pods are self-contained, so if there is contamination in one then the others will be unaffected. If necessary, they can be decontaminated via vaporized hydrogen peroxide, which may be important – particularly given the contamination discussions relating to minute mouse virus (MMV) and other contaminants. Moreover, self-containment makes it easier to scale the cleanroom area up and down and thus achieve capacity flexing.

The concept of the pod was devised by a team working with individual patient samples, who needed to scale up their cleanroom area but were fed up with the need to revalidate traditional cleanroom areas whenever they expanded their processing space. They wanted to make a cleanroom “box” that could be placed inside a shell building, and which can then be multiplied without interrupting existing processes. When I saw the outcome – cleanroom pods – I realized that they were ideal for single-use process unit operations or small-scale filling systems. The pod forms a self-contained, mobile containment around processing units – you no longer need just a single-use unit operation, but can implement the unit into an environment with similar flexibility.

Pods vs the traditional cleanroom

Being inspired by a technology is one thing, but making it work on a practical level in the pharma industry is a challenge. The early pods I saw were good, but certainly not perfect and improvement via understanding industry needs was essential. If compact cleanroom technology is to make a mark on the industry then it must be robust and associated with quality – we want the technology to be considered a mobile device rather than a rotary phone. To this end, it is important to use the right materials. Steel, while well established, is too heavy to offer mobility and can rouge over time. The material should be lightweight, but also have the longevity and strength to endure being moved around – we decided to go with aluminium.

In our eyes, the technical challenges of pods have been largely overcome – they are not difficult to design or build, and we believe users will be able to buy these systems off-the-shelf in the future. In addition, industry acceptance, if not demand, of flexible cleanroom technology is rapidly increasing, with a number of vendors now pushing modular cleanroom concepts. One of the biggest obstacles to more widespread implementation is that manufacturing companies tend to focus on cost per square foot – companies want to directly compare the cost per square foot of a pod or other solution to that of a traditional cleanroom, and they fail to fully consider the total cost of ownership. This is something commonly seen with new technologies in the pharma industry – it was the same for single-use process technologies in their early days; companies viewed the ongoing cost of consumable bags as a negative. Slowly, the industry started to realize that although a stainless steel vessel negated the need to buy a bag at around $500 or so, it instead incurred thousands of dollars of cleaning, energy and set-up costs. Once companies became more aware of the hidden costs of stainless steel, the adoption of single-use technology accelerated and today, single use process technology adoption is commonplace.

The cost per square foot for a podular cleanroom (and often for modular cleanrooms too) is usually higher than for traditional cleanrooms. The value of an alternative to standard cleanroom infrastructure can be seen, however, once you consider the total cost of ownership. When installing a new cleanroom infrastructure, would you prefer a hundred workers at the site for six months, which also involves insurance, supervision, laydown area and potential mess, or five people at a site for a matter of days? We recently installed seven pods at the University of Tennessee in four hours. The most time consuming aspect is interconnecting electrical and supply lines, which takes around three or four days.

Mobility Means Flexibility

By Stephanie Sutton

Constructing a traditional cleanroom tends to be associated with a number of necessary evils – mainly the time required for construction and the fact that companies invest in one room, in a fixed location. If the facility is decommissioned then the cleanroom environment can’t be redeployed elsewhere. Today’s modern facilities are usually designed with flexibility in mind; for example, it is possible to build flexible rooms with fixed utility stations in the ceilings and walls that allow processes to be moved around, but there are limits to how flexible hard infrastructure can be. To address this problem, a number of vendors offer construction services in terms of modular and portable cleanrooms.

Modular cleanrooms

Modular cleanrooms can be seen as a more flexible option than traditional cleanrooms because they can be installed quickly, with little onsite disruption, and relocated or upgraded as needs and capacities change. They are used as both temporary and permanent cleanroom facilities – often being used to extend an existing cleanroom. Modular cleanrooms must sit within a shell facility and are made of prefabricated wall and ceiling panels. The main benefits of a modular cleanroom is flexibility – a modular cleanroom can be small or large, and easily expanded by adding new panels. A modular cleanroom can also be built around existing equipment and can be relocated elsewhere in the facility – or taken to another facility and re-assembled if required.

Soft and hard walls are available for modular cleanroom construction. Soft walls are not suitable for all cleanroom applications, particularly the most demanding applications, but can be an economical solution for certain projects, such as some medical devices. They are often used to upgrade a specific area. Generally, a soft wall is a clear plastic panel supported by stainless steel frames. Hard walls are rigid and suitable for a wider range of cleanroom classifications.

Portable cleanrooms

The portable cleanroom is constructed offsite and can be moved to wherever required. In some cases, the cleanroom is completely contained – one common method is to build a cleanroom environment inside a shipping container – which negates the need for a shell building and allows the cleanroom to sit, for example, in a carpark. Usually, some site work is required first to prepare for the arrival of the cleanroom. Other portable cleanrooms are designed to sit within shell buildings. In almost all cases, portable cleanrooms are designed for temporary or short term use only. Some of the main users of portable cleanrooms in the pharma industry are small manufacturers who are short on space and need temporary extra capacity. Portable cleanrooms don’t have to be purchased – they can also be hired.

The sweet spot for flexibility

Ultimately, whether you choose a standard or flexible cleanroom will depend on your needs. The main benefits of flexible cleanroom technology lie in process-intensified manufacturing applications, when companies are unsure of future demand or are manufacturing multiple products. At the moment, there is a lot of focus on flexible manufacturing in the cell and gene therapy field. These therapies are advancing rapidly but there is some confusion over how best to manufacture them – certainly, with one batch per patient, they don’t fit with the traditional manufacturing model. A big question with these therapies is: should manufacture be centralized or decentralized? At the moment, companies want manufacturing capacities fast but there is a reluctance to spend time and money on hard infrastructure when things may change. With pods or other flexible solutions, manufacturing can first be centralized but if it needs to be decentralized later then it’s no problem – just take the pods out and move them.

In my opinion, if your plans are subject to change then it’s far better to have a flexible manufacturing solution that you can move around and adapt as you please. At the moment, many aspects of pharma manufacturing are changing – there is a huge drive for smaller footprints and intensification – particularly with continuous bioprocessing being adopted – and this allows the industry to consider more compressed cleanroom areas. For example, given that we now have concentrated media which can be fed directly into the stream via single-use systems, companies in the future may no longer need a media prep step. If you’re using pods then you can just refit your media prep pod into something else or move it elsewhere. The idea of pod farming is something that was raised by a client of ours recently. What if everything could be manufactured in clusters of pods? Instead of having a huge facility could you share a plant with other tenants and share the admin, quality management and quality assurance costs?

I think some of the most exciting ideas for the future of flexible manufacturing will come from the end users in the industry. This year, Pfizer received a Facility of the Year award for the Equipment Innovation category – and our pods played a part in that. We are in a consortium with Pfizer and GEA to design and build a portable manufacturing environment for continuous oral solid dosage production. It can be shipped to any location to get medicines to patients when and where they are needed.

Given my expectations for the future of flexible cleanrooms, is there still a place for traditional cleanrooms too? Absolutely. Traditional cleanrooms are not going away and will be invaluable for large-scale projects – you can’t fit 15,000-liter bioreactors in one of our pods! The trend is moving towards continuous production with smaller equipment, but this won’t be suitable for all medicines. Some companies will continue to need huge stainless steel infrastructure. Once again, I visit the analogy of single-use technology. Over the years, many have asked if we will still need stainless steel in the future – yes, we will. Single-use adoption started slow, but is growing exponentially and will continue to do well because of its flexibility – and we expect to see the same trend with mobile and flexible cleanroom solutions; a hesitant adoption, which starts becoming a fast one. But this doesn’t mean that other technologies will go the way of the dinosaurs. More flexible technologies, such as podular and modular options, will simply give companies more tools to work with to improve drug manufacturing.

This article is based on an interview with Maik Jornitz, CEO and President, G-Con Manufacturing, Inc., College Station, Texas, USA.

- S Sutton, “Keep it Clean”, The Medicine Maker, 21, 20–27 (2016). Available at: bit.ly/2fFcbhX.

Maik Jornitz is CEO and President, G-Con Manufacturing, Inc., College Station, Texas, USA.