Saving the World, One Vial at a Time

SiO2 Materials Science joined Operation Warp Speed in the summer of 2020 to produce its plastic-glass hybrid vials for the COVID-19 vaccine rollout in the US. Lawrence Ganti, Chief Business Officer, explains how they quintupled their workforce and increased production capacity 12-fold in just a few months.

Tell us about the history of SiO2...

SiO2 Materials Science dates back to 1910. In those days, the family business, led by Mauri Abrams, worked on accounting systems and various new technologies for the US government. In the 1950s, his son, Bobby Abrams, took the helm and built one of the largest dairy manufacturing plants in the US. Over the years, Bobby has invented a number of products, such as the first private labels for the dairy industry to desiccated plastic vials for diabetic strips, the infant sippy cup, and airtight vials for drugs of abuse testing. In 2012, Bobby – who remains our CEO – was approached by the Children’s Hospital at Stanford University. They were unable to save the lives of 20–25 premature babies each year due to adverse reactions to sub-visible particles found in traditional glass syringes and vials used with their medicines. Bobby then set out to invent an inert container to house modern biological drugs – and that was the birth of SiO2 Materials Science.

How do your vials and syringes differ from traditional glass-based technologies?

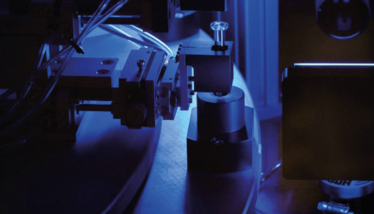

We’ve spent the past decade, and more than $500 million in research and development, to invent a technology that fuses plastic and glass. The technology we’ve invented looks and feels like plastic, but on the inside they have a nanoscopic layer of pure glass (SiO2), which keeps the oxygen and moisture out of the plastic container. Unlike regular glass, there’s no delamination – the appearance of visible flakes or glass lamellae, which can be a risk to patients if undetected. You can also freeze these vials to cryogenic temperatures.

Then the US government got in touch…

We were using the hybrid material to make syringes, mainly for biological and advanced therapy products. Then, when the pandemic hit, the US government were looking for glass vials that were outside of the existing glass supply chain, and could also meet certain requirements around protein aggregation, interaction with oil, ability to withstand low temperatures, and so on. They got in touch to inquire about our technology – and our ability to scale. We ended up being a good fit and set about increasing production – rapidly. We had to go from making 10 million vials per year, to ten million vials per month for the COVID-19 vaccine rollout in the US.

The pharma industry has been dealing with glass shortages for a number of years now. Usually when a company develops a drug, they have a period of five-plus years to plan and ensure they have all the supplies they need. But the COVID-19 pandemic suddenly raised the demand for glass, with manufacturers needing to produce millions of vials in a matter of months. For traditional glass vial manufacturers, it might take 18–24 months to achieve what we were able to do in four because they’re all using the same raw materials. We’re outside of that supply chain because our technology is predominantly plastic.

It also helped that we were already working with several large pharma companies prior to the pandemic. We had our technology being used in close to 20 clinical trials and had launched a syringe with Novartis for Lucentis.

What were some of the challenges involved in increasing capacity 12-fold in just a few months?

The technology itself is inherently scalable – so there weren’t many problems from a scientific perspective. Rather, the challenges were logistical in nature. Pharma, as we all know, is highly regulated. So whenever you increase capacity there’s a lot of paperwork involved. And scaling at the pace we did, we found the sudden uptick in the amount of documentation we had to fill out slowed things down quite a bit – though we did, of course, appreciate why it had to be done. Another perhaps more challenging aspect of the scale up was recruitment. Under normal circumstances, you might hire 100 people over the course of a few months. And of those 100 people, five might not work out. But when you shrink that timeline to a week or two, that 5 percent might rise to 10 or 20 percent. In the end, we had to over hire knowing that there would be some attrition.

There are several additional challenges associated with quadrupling your staff. For example – and I sometimes joke about this – you don’t think about potato chips! Where will everyone park? Where is everyone going to eat their lunch? Where will they take their breaks? Our break room was set up for 100 people – not 500. Add to that the need for social distancing and you quickly run into some real logistical challenges. In the end, we had to set up tents and tables outside (luckily it’s warm enough to do that here in Alabama). We also had to secure parking places with the local town to ensure we weren’t creating any problems with our employees parking by the street on the grass. Many of these things get taken for granted – I could add cyber security and database scaling to the list – but they are essential to supporting a sudden increase in production. We had to be flexible, and from a management perspective, decisive. It’s about moving forward quickly in a coordinated fashion.

Finally, we faced challenges rapidly procuring the required hardware. We were working with a number of different partners on the equipment builds, all of which had to be coordinated to ensure everyone was on the same page – they’re scaling too and our timelines need to match. We also had to ensure our partners understood the importance and urgency of what we were doing.

Where are you up to now in terms of production?

In terms of doses, we reached the 100-million dose milestone. So that means we’ve shipped more than 10 million vials (they each hold 10 doses). We’re now averaging around eight to nine million vials per month, so we’re really rocking – producing and shipping and producing and shipping... But we’re not just supplying vials for the mRNA COVID-19 vaccine in the U.S., we also have customers in Europe, Asia, and South America that are testing the vials for their vaccines. And of course, we are also still producing syringes and other vials for key biological drugs in clinical development.

How did your staff rise to the challenge?

The effort that people have put in has been nothing short of inspiring. It’s been 24/7, working 80-90 hour weeks, with some working through Thanksgiving, Christmas, and New Year. The people on the production line, in the quality teams, the program managers who look after the schedules – and all their related supervisors and managers – have been, I would say, maxed out. We have a team that physically build the manufacturing technology, as well as testing and validating them. Normally, it might take six months to get a machine up and running, but they’ve had to shrink that timeline to a matter of weeks – days even. But it isn’t just the manufacturing staff who have put in extra hours. Going back to staffing, consider the HR manager who had to send out offer letters to hundreds of people, facilitate criminal background checks, ensure their benefits, 401Ks, and healthcare plans are set up. Everyone has had to pull together to scale up so fast.

Given the sheer number of vials, how do you deal with sustainability?

Once used, our vials are considered medical waste, which means they’re not recyclable; however, I will say that the process we use to make our vials is more sustainable than traditional glass vials. Making glass uses a tremendous amount of water and heat – energy, in short. Our process is “dry”, so there’s very little water involved and much lower temperatures. So our carbon footprint is relatively low.

How has COVID-19 changed the pharma industry – with particular regard to glass vial usage?

The pharma industry is always slow to adopt new technologies. But sometimes it just takes one or two trailblazers to make everyone realize, “Oh, it does work!” We’ve seen that with the initial success of immunotherapies, which prompted hundreds of companies to work on them. I think COVID-19 has forced companies to adopt new – or perhaps “emerging” – technologies and ways of working. Working from home is the obvious example of a trend that has been hugely accelerated by the pandemic, and I think the adoption of our technology fits into the same category.

But just as working from home was already prevalent before 2020, we were already in discussions with many companies. And most – I’d say 70 or 80 percent – of large pharma companies had already tested our technology with positive results. Under normal circumstances, it might be another 5–10 years or so before we might see that translate into a much larger market share. But with companies like those leading the COVID effort now using our vials at scale, we expect to see that timeline reduced considerably – just as many people will probably spend some time working from home once we can all safely return to the office. Plus, there are other pre-existing trends working in our favor. We see many companies moving into the “bioengineered” or biological space, such as antibody drug conjugates, cell and gene therapies and other protein-based therapies. These are all technologies that are more sensitive subvisible particles, silicone oils, and metal ions- all traditionally associated with glass. Our technology is well suited to those kinds of therapies and we are already seeing an uptick in interest from companies developing gene therapies and bioengineered therapies for oncology and immunological diseases. So, in short, yes – I think COVID-19 has changed things for good.

What does it mean to everyone at SiO2 to be involved in COVID-19 vaccine rollout?

As I’ve discussed, there have been huge efforts – and sacrifices – made across the company. But I think everyone understands and takes a great deal of pride in the role we’re playing in ending a deadly pandemic – “saving the world one vial at a time,” I sometimes like to say. Leaders often talk about the importance of having a clear purpose to what your organization does. We certainly have that and I think that’s been the key to our success so far.

Over the course of my Biomedical Sciences degree it dawned on me that my goal of becoming a scientist didn’t quite mesh with my lack of affinity for lab work. Thinking on my decision to pursue biology rather than English at age 15 – despite an aptitude for the latter – I realized that science writing was a way to combine what I loved with what I was good at.

From there I set out to gather as much freelancing experience as I could, spending 2 years developing scientific content for International Innovation, before completing an MSc in Science Communication. After gaining invaluable experience in supporting the communications efforts of CERN and IN-PART, I joined Texere – where I am focused on producing consistently engaging, cutting-edge and innovative content for our specialist audiences around the world.