Nonprofit Model for Manufacturing

All companies claim to put patients first, but how true is that really when the corporate pharma business revolves around profits? Civica Rx is approaching generic drug manufacturing using a nonprofit model – and it’s working. We get the story behind their facility in Petersburg.

Stephanie Vine | | 13 min read | Technology

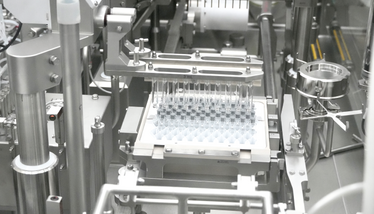

Groninger outer bag removal

Civica Rx was launched in 2018 as a nonprofit drug firm with a focus on essential generic medicines that were being under-delivered in the US market. The problem – in Civica’s words: “Unfortunately, when a supplier is able to concentrate market power with [essential generic] drugs, they are able to wield an exorbitant amount of influence on the price.”

The company was founded by several US health systems (Catholic Health Initiatives; now CommonSpirit Health, HCA Healthcare, Intermountain Healthcare, Mayo Clinic, Providence St. Joseph Health; now Providence, SSM Health, and Trinity Health) and philanthropic organizations (the Gary and Mary West Foundation, the Laura & John Arnold Foundation, and the Peterson Center on Healthcare). Martin Van Trieste, former chief quality officer at Amgen, came out of retirement to sign on as Civica’s CEO – a role he took on with no compensation. At first, 14 generic medicines were identified by the company as being a priority.

Six years later, Civica is supplying nearly 80 different generic medicines to member hospitals – and has provided over 185 million doses to date. It has also opened its own manufacturing facility in Petersburg, Virginia, with the capacity to produce 90 million vials and 50 million pre-filled syringes of medicines every year. Crucially, a study published in NEJM Catalyst found that the company had been able to improve generic drug access through its unique model (1). Civica has also expanded its ambitions to new areas, such as insulin. In 2023, the state of California announced a 10-year agreement with Civica for the manufacture of “CalRx” insulin.

Jason Winfield, site director of engineering and technical services at Civica, thinks that much of the success comes from the company’s can-do attitude and the lack of bureaucracy. “From the start, Martin made it our mission to do what’s in the best interest of the patients. We continue that motto today. A lot of people are very engaged in our mission – there are a lot of good names on our executive team. As a nonprofit, we are able to come to work to help patients rather than earning extra dollars shareholders. Not having to go through third party distributors, distribution centers, and pharmacy managers has allowed us to get products to hospitals and patients at a reasonable cost.”

Laura Sildon, Executive Director of the Civica Foundation with Brian & Joshua Davis, who live with Type 1 Diabetes

Bringing it home

Van Trieste has now headed (back) to a well-deserved retirement, but Civica continues to grow. In March 2024, the company announced a collaboration with groninger and SKAN for new filling lines for their facility. Winfield told me more about the decision – and groninger and SKAN also gave their input.

“This was a really rewarding project to work on,” says Matt Clifton, business development manager at groninger. “A lot of people are affected by drug shortages – including people I know personally – in the US. Civica has a real patient-centric focus. I always focus on getting the best machine for the client but this project felt close to the heart.”

But why build your own facility – especially in an expensive Western country like the US?

According to Winfield, there has been a big focus for some time on bringing production closer to home. Indeed, the challenges of globalized supply chains is something that Van Trieste has previously discussed with The Medicine Maker. Winfield says, “A lot of pharmaceutical manufacturing takes place in India and China, but there have been widely publicized issues with sterile injectables. And although India is a great provider of APIs, they get a lot of their precursors from China. During the COVID-19 pandemic, materials stopped moving – and this hasn’t ended with COVID; there are still ongoing challenges in supply chains.”

Docking a Beta Canister on an MTI (Material Transfer Isolator) from SKAN

Civica already had diversified suppliers of APIs from the start, prioritizing the US and Europe, but drug shortages and the industry’s reliance on existing supply chains inspired the company to open the Petersburg plant. But even with its own manufacturing capacity, Civica doesn’t put all of its eggs in one basket.

“No more than 50 percent of our hospitals’ demand comes from any one facility,” says Winfield. “We’ve moved things around strategically; if there is an upset in any facility manufacturing our private-label drugs, we can source it from a different place. We have second and third line suppliers, but our Petersburg facility is the ultimate control. We can manufacture our own medicines, across the spectrum of presentations, including vials, syringes, and cartridges. If any of our suppliers are unreliable or if there is a market shortage, we can quickly ramp up manufacturing at Petersburg. We’ve also got technologies at the plant that allow us to have quick transfer of products in and out.”

Groninger nest filling line with SKAN isolator2

Choosing equipment – and suppliers

Winfield got his role at Civica in 2020 – after the decision to build a facility had already been made. Two weeks before he was officially due to start his new role, he was brought in for critical decision making on what filling lines to purchase. An architect engineering general construction firm had proposed using filling lines from different vendors – as well as isolators from different vendors. “It didn’t make sense to me. At the time [COVID], there were big challenges in resources – including people, materials and equipment. I wanted to standardize how we ran the facility,” explains Winfield.

“Big challenges” is perhaps an understatement. During the pandemic, companies with large manufacturing contracts, such as for vaccines, were buying out equipment, consumables, and PPE. Many companies didn’t yet know what their manufacturing processes were going to be so they hedged their bets. “Folks were buying every single-use mixer they could,” says Winfield. “At one point, there was an 80-week lead time on single-use bags. After COVID, many items were thrown away because they were never used at the commercial scale. Regulators are now starting to look at manufacturing processes and controls – and encouraging companies to be more careful. For example, if you throw away 25 percent of your product because the containers aren't sealed, it's not okay to do that anymore because you are taking away consumables that could be used by someone with a more controlled process.”

Winfield made calls to vendors he had worked with previously. After a bidding process, a deal for filling machines and isolators was agreed with groninger and SKAN. Although they are separate companies, only one contract was involved because the companies already have their own corporate partnership in place.

“SKAN has always focused on high quality containment,” says SKAN’s Marc Suter. “Back in the 1990s, the industry started thinking about separating the filling process and began looking into isolator technology. We were one of the first companies to build a commercial-scale filling isolator in Switzerland and with the industry heading this way it made sense to partner with a filling company. groninger is an expert with filling lines, and we had a similar mindset and similar leadership in technology, so we joined forces. Our goals are the same: to make reliable lines that are easy to handle for manufacturing products. Today, we collaborate together on a lot of different products.”

Docking a Beta Canister on an MTI (Material Transfer Isolator) from SKAN2

The companies have their own separate products and different areas they want to grow in, but where there is crossover there is close collaboration. Nevertheless, they did need to reassure Civica that two companies were definitely better than one. Clifton says, “We’ve been working together for years. Many of the long-standing staff at each company are very familiar with one another. In many cases, machines are designed together. However, some people do have questions about how the process works when you have two separate companies involved. They may feel they have to send two purchase orders and worry about things falling through the cracks. But we trust one another enough that one company takes the lead and responsibility for the project. A turnkey approach makes it easier for the client.”

Talking about the Civica project, Suter adds: “Civica were using a greenfield site and it was a very ambitious project. As a vendor you see a lot of ambitious plans – and you also see plans that fail. How Civica approached everything was amazing. Today, the facilities are up and running. Everything has been installed and qualified.”

One of the main reasons that Civica went with well-known companies for process equipment was simple: you know what you’re getting from an established name in the market because the reputation is clear. “Quality and reliability should always be at the forefront. Cheap capital ultimately leads to bad operations,” says Winfield. “Saving a few million dollars on a piece of capital or other shortcut will cost you a lot more in unreliability and rejected batches in the future. Buying good quality, reliable equipment sets you up for a culture of success. Bad equipment also affects people – who wants to fail? I wouldn’t hang around for long at a company that was taking shortcuts.”

Shortcuts aren’t just investing in the wrong equipment; many companies try to cut costs by getting more life out of older technologies as opposed to investing in something new. Networks that don’t invest run the risk of requiring complete remediation in the future. “Unreliable lines also mean that you’re asking staff to do more with less,” adds Winfield. “This type of cultural pounding can really demoralize people over time.”

The technology itself is only one aspect of selecting the right suppliers. You also need to consider how the vendor will support you. Suter says, “There are many vendors out there that will all give you a great sales pitch, but it comes down to trust. Before committing, you need to ask yourself: do I trust this partner? Can this partner get me to the finish line on time? The finish line is not equipment delivery; it is when everything is qualified and approved by the authorities.”

“Find a vendor that will help you install and qualify the equipment – and do whatever else it takes to make the project a reality and maintain the equipment for its life cycle,” adds Clifton. “Don’t forget to check out your vendor’s service capabilities because this is something companies often don’t look at until they actually need it.”

As well as technological support with servicing, Winfield explains that time zones are a common issue. “There are a lot of amazing technology companies in Europe, but when you’re stateside you really need stateside support,” he says. “If I have something that is broken, I need your help today. I can’t wait 8 or 12 hours until the clock resets on the other side. Everything in this project from installation, to start up, commissioning, and so on was based out of the US.”

Cartridge in process control (weight check) on a groninger line

Also think about the capabilities when times are rough. The COVID-19 pandemic has taught us all about preparing for unexpected disasters. “Since this project took place during the pandemic, travel was curtailed for many,” said Suter. “Usually, vendors offer facility tours or site tours of other facilities using their technology, but we had to use virtual reality for mock ups and tailoring the line. This worked really well, but you have to have those capabilities in place and be adept at using them to make the project a success.”

Civica has installed two full filling lines, which include four SKAN isolators (three as part of the filling lines and one as a material transfer isolator). One line is an integra line for bulk vials, and includes a tunnel and capper. The second line is for nested RTU containers. Both are flexible enough to cope with frequent format and product changes, and they have been designed to minimize product loss.

“Because the isolators are all manufactured by SKAN, it allows me to reduce my overall spare parts in the facility because there's a common spare part to each one,” says Winfield. “I also have increased operational savings when it comes to HEPA certifications because I don’t have to call in different vendors. This is also useful for audits and inspections. The true cost of ownership goes far beyond what the capital is.”

The Medicine Maker Presents:

Enjoying yourself? There's plenty more where that came from! Our weekly Newsletter brings you the most popular stories as they unfold, chosen by our fantastic Editorial team!

Disrupting the status quo

From the very start of Civica, Clifton says that the company was unique. “A lot of people in the industry were watching them closely. They had smart people on the business side and significant industry leadership with a ton of manufacturing experience. However, I think there was some doubt early on about whether they could pull it off and if there would be any compromises on quality. But they’ve done it – their products are excellent and their facility is one of the best facilities I’ve visited. They use high-end solutions and they understand what they are doing. They are top tier in the industry.”

“It’s hard not to feel personally moved when you hear the story behind Civica,” adds Suter. “Somebody needs to tackle drug shortages, but it may not be profitable to do so for some companies. The result is that patients have to go without their medicines. I’m proud to be part of a project that is trying to change that. Civica isn’t just focused on generic drugs; they also have plans to make affordable insulin. I really wasn’t aware of how difficult the situation is in the US compared with Europe, where I am based. If you follow through and stand with something, you can make changes in this industry. It’s been amazing to watch what Civica has done.”

In some ways, it can be said that Civica found success in its insulin plans before supplying a single vial. In 2022, Civica announced plans for an insulin with a price of $30 for a 10 mL vial, and $55 for a five pack of 3 mL – which includes the cost of distribution and pharmacy dispensing. In 2023, the price of insulin in the US was capped at $35 per month for Medicare Part D, as part of the US government’s Inflation Reduction Act. Insulin makers Eli Lilly, Sanofi and Novo Nordisk have all since reduced their insulin prices. Although the Inflation Reduction Act will have played a large part in the companies’ decisions, it’s also likely that they were feeling pressure from Civica’s 2022 announcement.

Groninger vial filling line with SKAN isolator, branded integra

Winfield says, “Civica put out a public statement in 2022 and we meant it. I’m not an industry expert on pricing or pharmacies, but ultimately other countries are able to provide affordable insulin to their citizens so there’s no reason why this can’t be done in the US too. We're not naive to think that we will take over and supply the world with insulin from our Petersburg site, but we hope we can prove to the industry that it is possible to sell insulin for less – and that others will follow.”

Companies need to make money and they should be allowed to do so. Not everyone can be a nonprofit (although more nonprofits may certainly benefit the world), but the industry must find a way to address drug shortages while balancing profits. Perhaps this means rethinking certain aspects of business. Civica will continue to pursue its unique model, but companies like groninger and SKAN also have a role to play.

Clifton says, “It’s our job to make the most efficient machines possible that can deliver the best products while helping to lower manufacturing costs. That has all come through innovation, which we don’t want stifled by companies becoming unprofitable. I don’t think the problem lies with the companies, but more with certain healthcare systems. Change is possible though – as Civica has shown.”

Civica is supported by a number of partners and supporters. If you are interested in helping the cause, get in touch.

Top Tips For Procuring Equipment

- Always prioritize quality and performance

- Be as cost effective as possible. This is not just about the cost of the initial investment; also pay attention to the cost to operate and overall cost of ownership.

- Consider vendors with experience in similar projects; for example, a company that has worked within the government system and US funding will be well placed to do similar work.

- Understand what timezones your vendor works in and what geographies technical experts are based in for services.

- Consider a brand that is already trusted in the industry; it can give you immediate confidence in your equipment.

- Check the supplier can meet your timelines and schedules.

- C Dredgs, S Scholtes, “Vaccinating Health Care Supply Chains Against Market Failure: The Case of Civica Rx,” NEJM Catalyst, 4 (2023). DOI: 10.1056/CAT.23.0167

Making great scientific magazines isn’t just about delivering knowledge and high quality content; it’s also about packaging these in the right words to ensure that someone is truly inspired by a topic. My passion is ensuring that our authors’ expertise is presented as a seamless and enjoyable reading experience, whether in print, in digital or on social media. I’ve spent fourteen years writing and editing features for scientific and manufacturing publications, and in making this content engaging and accessible without sacrificing its scientific integrity. There is nothing better than a magazine with great content that feels great to read.