Welcome to the Era of Smart Solid Dosages

On-dose authentication technology can help deter counterfeiters, while also helping patients better engage with their medicines

Ali Rajabi-Siabhoomi, Gary Pond | | Longer Read

sponsored by Colorcon

Globalization and increased outsourcing activities have led to some very complex supply chains for pharma manufacturers – and that means an increased risk of counterfeiting and diversion, putting both brands and patients at risk. Today, many countries have implemented serialization requirements for secondary packaging to track and trace products throughout the supply chain, and many pharma companies also add additional security features, such as holograms and security inks to their packages to further deter counterfeiting. All these moves have huge benefits. But the industry needs to go even further.

One of the main channels for counterfeiting today is online illegal pharmacies – with hundreds of new outlets appearing online each month. These pharmacies have increased significantly during the COVID-19 pandemic – as today there is even more desire from consumers to shop online, with medicines being no exception. When searching for online pharmacies, it’s common to find links to both legal and illegal pharmacies; more worryingly, it can be hard for patients to tell the difference. Random sampling by the FDA of 10,000 online pharmacies, found 97 percent of them to be operating either illegally or not following regulations. The World Health Organization reports the chances of a patient getting a counterfeit drug product online is over 50 percent.

At the same time, counterfeiters are becoming more adept at copying many aspects of a medicine, including the package, label, the foil induction seal, and even the appearance of the tablet itself. Moreover, counterfeit, and diverted medicines can also find their way into legitimate supply chains. In one recent example; Gilead warned of counterfeit versions of two of its top-selling HIV medicines in the USA. These drugs are expensive and considered specialty products; they are only distributed by a small number of authorized wholesalers in the USA, and the FDA requires them to be dispensed in their original packaging. You would expect that it would be highly difficult to counterfeit these medicines, but the counterfeiters used genuine Gilead bottles and added a counterfeit foil induction seal. The package looked genuine, and there wasn’t an easy way for patients or people in the supply chain to quickly determine if the actual tablets were real.

Not only can counterfeit medicines potentially contain dangerous ingredients, but they often have no therapeutic effect. HIV is a life-threatening disease and a patient’s viral load can quickly go out of control if they stop taking genuine medication. More and more, counterfeiters are targeting valuable medicines like this because of high demand from patients – and the high monetary rewards.

At Colorcon, we’ve been looking at ways to secure medicines at the individual dose level, so even if the original packaging is taken away, the actual tablet can still be authenticated.

For the patient

At Colorcon, our purpose is “To improve health and wellness through convenience, compliance and safety.” We offer a range of pharmaceutical coatings, excipients, and formulation development assistance, including process guidance, for oral solid dosages. We don’t work directly with patients, but our customers – the pharma companies – do! We feel it is our responsibility as a leader in solid oral dosage forms and coatings to innovate and bring solutions to the market that help pharma companies to protect patients. When thinking about innovations that can help prevent counterfeiting, we also realized that the same technologies could transform how patients engage with their medicines.

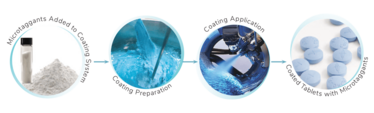

We believe there are opportunities to better secure medicines by targeting protection down to the dosage level. A film coating, such as Colorcon’s Opadry® system, already provides many positive benefits including functionality and differentiation. Now, we can also add molecular and microtaggants to the coatings. Our portfolio of on-dose authentication solutions, SoteriaRx®, brings to market the advanced technologies from TruTag and Applied DNA Sciences. The taggants cannot be detected by the human eye, but the tablet can be scanned by an in-field reader to confirm the authenticity of individual tablets. The concealed signature of a taggant can contain information such as product, dosage, and manufacturing site. Think of it as adding an invisible barcode to individual tablets – and, as the technology is so unique, it’s almost impossible to reverse engineer or copy.

But this technology doesn’t just help deter counterfeiters; it can also be used to better engage with patients. Some pharma customers we are working with want to use the taggants in a very covert way (so only a small number of people within the company would know about the presence of the microtaggants), but others are interested in a more overt approach, including consumer participation, given that an increased number of people are buying medicines online. We’re now working on options that allow companies to engage with their patients and confirm the authenticity of medicines using a smartphone. When a patient scans a tablet to check authenticity, companies can also provide access to support materials, such as the product leaflet, information that explains the benefits of the medicine, the importance of adherence, what to do if there are side effects, and even the ability to opt into reminders to take the medicine at the right time. In other words, such “smart” medicine not only brings authentication closer to the patient but also helps them feel more comfortable with how they take the medicine.

Non-adherence is a huge challenge for healthcare systems – and patients may have many reasons for not taking their medicine. Children often dislike the medicine because of the taste, while elderly patients may have dysphagia. Carefully selecting the right shape and size tablet is very important to ensure that as many patients as possible can take the medicine comfortably. For many adults, however, a significant cause of non-adherence is simply the patient mindset; if a patient has a negative experience or believes that the medicine will not work for them or may harm them, it becomes a very powerful motivator for non-adherence. Patients can also be influenced by news of counterfeit medicines, which can make them lose trust in the manufacturer, or even the pharmaceutical industry. The industry is very concerned about how counterfeits may impact brand integrity and corporate reputation – further harming more patients who may fail to take their medicine as a result.

Simply put, counterfeiting and product diversion have the potential to harm patients and brands everywhere.

A smarter future

Smart medicine is an increasingly important topic for the pharma industry as companies look for ways to engage more with patients and encourage them to take their medicines as prescribed. Many factors contribute to making a medicine smart, including what goes into the packaging, what goes into the dosage form itself, and how the patient may engage with their medicine. All patients can benefit from greater information and support that ultimately improves safety and adherence. Wouldn’t it be fantastic if they could get this directly from the tablet through an integrated smartphone?

We’re very positive about the future of SoteriaRx®. Especially following the FDA’s issuance of guidance on the use of physical-chemical identifiers (PCIDs) in solid oral dosage forms; in brief, PCIDs can be incorporated into already approved drugs as a Level 1 post-approval change. We’ve aligned our portfolio of authentication approaches with this guidance. We’ve also sought to ensure the transition to smart medicines is as smooth as possible for customers by demonstrating proof-of-concept with our coatings – and the manufacturing process is the same as for any filmcoated tablet.

If you want to explore what smart medicine can do for you, then we’re happy to discuss your requirements and provide implementation support.

Ali Rajabi-Siabhoomi is Vice President and Chief Scientific Officer at Colorcon.

Global Product Authentication Lead at Colorcon