Meeting the Demand for Cost-Effective Biologics and Advanced Therapeutics

The Critical Role of XCell® ATF System and KrosFlo® TFDF® System in Boosting Productivity of Upstream Process Intensification

According to BioPlan’s 2023 report on Biopharmaceutical Manufacturing, over 40% of industry professionals identified “Upstream: Continuous processing/perfusion” as a key area for evaluation and testing in the coming year, highlighting its growing importance in bioprocessing.

This surge in interest underscores the urgency for stakeholders to familiarize themselves with process intensification through perfusion. This method offers significant advantages over traditional batch and fed-batch processes, including improved efficiency and productivity.

In this context, we introduce Alternating Tangential Flow (ATF) and Tangential Flow Depth Filtration (TFDF), disruptive technologies transforming upstream process intensification for all modalities. Discover and learn how these innovations can revolutionize your biomanufacturing.

Webinar: Disruptive technologies transforming upstream process intensification for all modalities

Process intensification has been proven to lower the cost of goods, increase productivity, and reduce facility footprint. The webinar discusses how the XCell® ATF System and KrosFlo® TFDF® System enable upstream process intensification for multiple modalities including mAbs, recombinant proteins, and viral vectors to improve yield, cost, and time.

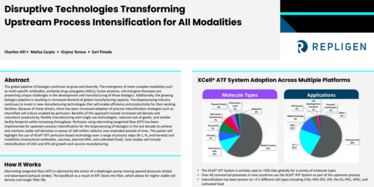

Poster: Disruptive Technologies Transforming Upstream Process Intensification for All Modalities

This poster highlights the use of XCell ATF perfusion-based technology to intensify CHO and SF9 cell growth and vaccine manufacturing. With over 500 adoptions at process and commercial scale across biopharma globally, the XCell® ATF System is a proven technology for intensified cell culture that exponentially boosts productivity, lowers costs, and expands capacity of existing manufacturing facilities in upstream bioprocessing.

Webinar: XCell® ATF System: Boost Your Bioprocess with Upstream Intensification webinar, Dec 2023

In this webinar, learn how the XCell® ATF System with its innovative Alternating Tangential Flow (ATF) technology unlocks up to 10x higher viable cell density (VCD) in half the time and up to 20x increase in productivity compared to traditional fed-batch processes, effectively reducing your cost of goods.

Video: How It Works, XCell® ATF System

Watch how the Alternating Tangential Flow (ATF) in the XCell® ATF System enables the extended cell culture run times to achieve higher viable cell density through the backflush action of ATF.

White Paper: Investigation of XCell® ATF Perfusion Technology for virus manufacturing process intensification at MSD Animal Health

Discover how MSD Animal Health improved their viral vaccine production by shifting from traditional methods to advanced perfusion techniques using Repligen's XCell® ATF Technology. This case study highlights a five-fold increase in cell density and viral output, showcasing scalability and efficiency improvements in vaccine manufacturing processes.

Webinar: Where and When to Apply Upstream Process Intensification Technologies

XCell® ATF System can be applied at multiple points in the upstream bioprocess depending on which challenges need to be solved. This webinar highlights the use of XCell® ATF Technology in seed trains and production bioreactors, demonstrating its scalability and efficiency in enhancing bioprocess productivity.

Video: The evolution of gene therapy manufacturing

This video spotlights the role of perfusion culture intensification using the KrosFlo® TFDF® System in scaling up virus-producing cell counts and specific viral vector productivity. The KrosFlo® TFDF® System can boost AAV and lentivirus production, ensuring high recovery and consistency from benchtop to large-scale operations.

Video: How It Works, KrosFlo® TFDF® System

KrosFlo® TFDF® (Tangential Flow Depth Filtration) technology unites the benefits of tangential flow (TF) and depth filtration (DF) in a closed and single-use solution that enables 1000 LMH. Watch the video to see how the technology works.

Application Note: Optimizing Lentiviral Manufacturing Economics with TFDF® Technology

This application note demonstrates how transitioning from traditional fed-batch production to a perfusion-based process using KrosFlo® TFDF® Technology improves productivity and economics across various metrics. Each step forward with TFDF® not only enhances process efficiency but also significantly reduces both process and product costs.

The adoption of XCell® ATF System and KrosFlo® TFDF® System marks a significant leap forward in upstream bioprocessing, offering not just a method to enhance productivity and yield but also a strategy to reduce overall costs and improve sustainability. These innovations from Repligen redefine the economic equation for biologic and advanced therapeutic manufacturing, establishing new benchmarks for operational efficiency and productivity. As we tackle the complex challenges of bioprocessing today, leveraging these innovations becomes crucial for the cost-efficient production of therapeutics. Repligen offers consultation with their Bioprocessing Specialists to discuss how process intensification with XCell® ATF System and KrosFlo® TFDF® System can improve the economics, productivity, and sustainability of the Upstream Cell Culture starting from process development all the way to clinical scale manufacturing.