All Eyes on Patches

Noven has developed around one-sixth of approved New Drug Applications for transdermal patches…

Noven is based in Miami, Florida, but in 2009, the firm was acquired by Hisamitsu Pharmaceuticals in Japan, which is the world’s largest manufacturer of transdermal patches. Today, Noven serves as Hisamitsu’s platform for US prescription pharmaceuticals and is involved in both the development and manufacture of transdermal patches.

The company’s successes? The Vivelle-Dot estrogen patch and its successor, Minivelle – the world’s smallest estrogen patch; the first two-drug combination transdermal product to be released onto the market – CombiPatch; and the only marketed transdermal patch for ADHD (Daytrana). The patches utilize Noven’s ‘DOT Matrix’ technology, which is a class of diffusion-based drug-in-adhesive patch technologies.

We connected with Noven via Jeff Mihm (CEO), Joel Lippman (Executive VP and Chief Medical Officer), Steven Dinh (VP and Chief Scientific Officer), and Patrick Gallagher (VP of Business Development) to find out more.

Please walk us through the main considerations for transdermal patch development...

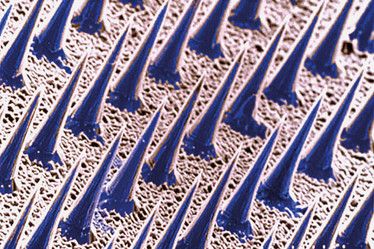

To develop transdermal patches you first have to appreciate that the skin is not a flat surface as it can deform according to the movement of the body. The skin is our largest organ; it protects us from the environment, helps us regulate internal functions, and provides an interface for sensation. Drugs must be able to permeate across this protective barrier to reach the intended target to produce the necessary therapeutic effect – all without eliciting local and systemic side-effects. Moreover, patch components have to store sufficient drug quantity for delivery, be physically and chemically stable over its shelf-life, be able to maintain adherence on skin during the period of use, be detached after the application period, and be left with minimal drug content after use.

It’s no easy feat to balance all of these factors! In addition, there are also a number of manufacturing steps and challenges to consider, including blending, coating, drying, die cutting and packaging.

A worker in the lab at Noven Pharmaceuticals. (Credit: Noven Pharmaceuticals)

How are patients reacting to this new wave of drug delivery?

In the US, most patients are used to pills. Our challenge is to educate both patients and physicians about the benefits of transdermal drug delivery systems (TDDS) – which can be done through product and patient educational materials. Two of the most important areas to address are proper patch application and providing patient support information.

TDDS have a number of advantages over traditional pills, including the ability to eliminate the first pass metabolism (where the drug concentration is usually greatly reduced before it even reaches systemic circulation), which allows us to introduce less drug into the body whilst still achieving the desired efficacy. A problem associated with oral delivery drugs is that the amount of drug entering the blood stream rises and falls. TDDS provide controlled delivery of drug in the blood and permit flexible dosing duration through patch removal. More broadly, TDDS can improve compliance by avoiding the need for frequent dosing, reduce GI and hepatic side-effects, and reduce the potential for abuse.

Any secrets to bringing transdermal systems successfully to market?

We all know that there are many challenges facing the branded pharmaceutical industry, so nothing guarantees that a product will be a commercial success. The foundation of commercial success starts by bringing forth a product that truly addresses an unmet need – this is something that all pharma companies should be striving for rather than simply bringing another “me too” drug to market in a different delivery form.

We believe that one example of this type of innovation is our patch for ADHD. As any parent of an ADHD child will tell you, frequently and consistently swallowing pills or capsules can be a very real challenge. We wanted to develop a once-daily patch that would release medication continuously until it’s removed to fit a child’s changing routine. The true design challenge of the product was getting the level of medication in the bloodstream to smoothly rise when the patch is applied and gradually descend when the patch is removed. Controlled delivery technologies normally provide continual release, and if anything, a slowing down to declining release. When developing our Daytrana patch, we had to achieve a growing release profile to meet the efficacy needs required to treat ADHD. We managed to design the patch so that the medication is continuously released until it is removed at the recommended 9-hour maximum wear-time or earlier.

Once-daily dosing was also an important consideration for us because it would eliminate the need for mid-day dosing in the school setting, which can be both disruptive to the classroom and embarrassing to the child. Building products around the needs of the patient and the caregiver is vital but so often overlooked.

What are your thoughts on the future potential of transdermal drug delivery?

The TDDS field is full of potential, both in passive and active delivery technologies. One exciting area is the idea of integrating both diagnostics and drug delivery capabilities into patches to create “smart” delivery systems. At Noven, we’re looking to expand our product development pipeline beyond the women’s health and ADHD therapeutic areas. We think there are far more therapeutic areas that can benefit from this non-invasive delivery method.