The Revolution Will Not Be Pencil-Sketched

A new 3D printer is ready to stamp on the accelerator of clinical testing

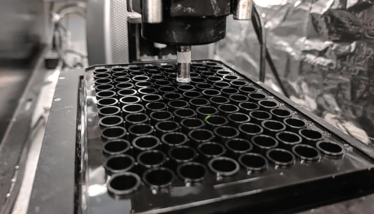

Researchers have given 3D bioprinting a speed boost by developing a printer capable of printing a 96-well array of samples in 30 minutes to accelerate preclinical drug screening and disease modeling (1). Leading the team behind the machine is Shaochen Chen, Professor and Chairman of the NanoEngineering Department at the University of California, San Diego. He hopes the printer will also overcome at least some of the current limitations of pharmaceutical and medical testing.

Therapeutic products are usually first tested on a 2D monolayer cell culture. The problem, however, is that many candidates fail at the transition phase; the few that work in 2D monolayer cell culture often fail in animal models (even humanized ones) and those that don’t may still fail when tested in humans due to unexpected incompatibilities. According to Chen, his team’s 3D bioprinting approach allows for the creation of tissue constructs that more closely mimic the complexity of human systems. The technology also uses a digital micromirror device that allows the machine to “skip” the line-by-line aspect of traditional 3D printing and go straight to “layer-by-layer.” This is the source of its fearsome speed.

Chen explains the system by analogy. “Imagine you were given the task of drawing a solid circle. If you were given just a pencil, you might first start by drawing the outline, then painstakingly fill in its interior, line by line. If you are then told to repeat this process to stack many circles layer-by-layer into a sort of 3D ‘cylinder,’ the fact that you only have a pencil means that this will take quite some time. If you were instead given a stamp in the shape of said circle, you could imprint the whole circle in a single stroke; repeating this across many pages is then a swift exercise. Our 3D bioprinting technology is like trading in the pencil for the stamp.”

The high-throughput 3D bioprinter (HT-3DP) technology has been licensed to a startup company called Allegro 3D Inc, of which Chen is a co-founder. The company has already begun commercializing the bioprinters, bioinks, and bioprinted tissues.

- S Chen et al., Biofabrication (2021). DOI: 10.1088/1758-5090/ab89ca

Between studying for my English undergrad and Publishing master's degrees I was out in Shanghai, teaching, learning, and getting extremely lost. Now I'm expanding my mind down a rather different rabbit hole: the pharmaceutical industry. Outside of this job I read mountains of fiction and philosophy, and I must say, it's very hard to tell who's sharper: the literati, or the medicine makers.