Matthieu Egloff and I are the co-founders of OUAT! – a life sciences marketing company with a large focus on creative digital experiences, including 3D modeling and virtual/augmented reality. Mathieu has a background in bioengineering, while my background is in marketing – and through the combination of this expertise, we aim to deliver simple and integrated digital tools. Both of us used to work for ATMI Life Sciences (now Pall).

At ATMI, Matthieu and I were responsible for the marketing and management of innovative bioreactors. At this time we were becoming frustrated by a key aspect of our jobs: we were selling very advanced, high-tech equipment, but our main selling tool was a simple PowerPoint presentation. When selling bioreactors, the same questions come up every time. What kind of footprint does it require? How does it fit with my process? How can I connect it to other equipment? With a PowerPoint presentation, we were only able to represent the labs of customers using squares, rectangles and circles, which isn’t the most effective method of understanding how new equipment will fit into a facility, or to help customers to imagine their lab of the future, so we started to experiment with other methods, such as 3D technology. 3D is incredibly useful because you can show off things that cannot normally be seen; for example, you can project the customer inside of a future environment or show them the inside of a product. And of course, VR can take this even further...

When we started OAUT!, we met someone who had nothing to do with the biopharma industry – who showed us VR. Anyone who has tried VR knows that the first time you experience it is a big “wow” moment. We fell in love with it and we knew it could be a powerful tool for biopharma applications. In Belgium, where we are based, there is a huge buzz around VR, which has helped us a lot – our work is actually now sponsored by the Microsoft Innovation Centre in Brussels.

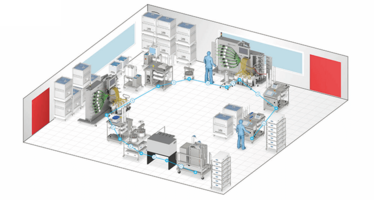

As Ian explained on page 33, we have combined VR with motion-capture technology to enable users to interact with a computer-simulated cell therapy facility. This project required huge efforts in the design of the facility and we rapidly started to think about a solution that would make this simple. This is how we created HakoBio – a web-based platform that can be used to create conceptual designs for processes. Bioproduction equipment is modeled in 3D and you can drag and drop products into your pre-configured room. IKEA actually does a similar thing with interior design. It’s very simple, but incredibly useful – and it’s amazing to think that there is nothing similar for the biopharma industry. One big pharma company recently told us that they still use pen and paper when thinking about their future labs. The other option is to work with large engineering agencies. We can’t replace such agencies of course, but we can be the link between the pen and paper, and the highly technical tools used by engineers – and support the conceptual design of processes and labs.

Pall isn’t the only company we are working with (customers include Sanofi Pasteur and Roche Diagnostics) – and one of the really fascinating aspects of my job is seeing the different ways in which people interpret and then implement the technology. For example, in recent work for a global company, we were interacting with people from Europe but they were building a new facility in the US. The team was multidisciplinary, comprising people from many different regions, and one of the main draws of the technology for them was the ability to easily collaborate because everyone could share the design and experience it. We’ve also worked with a CMO who wanted to use our platform to showcase their current and future capabilities, and demonstrate how flexible their infrastructures were.

Today we are expanding the database of 3D models to additional bioprocess equipment – and discussions with vendors are progressing well. To further open the field of possibilities and opportunities with our tool, we are also partnering with a company that is active in the capture and management of big data from connected bioprocess equipment. We are investigating how we can leverage the HakoBio platform to visualize and analyze a large amount of data – after all, labs produce a lot of data that can be difficult to visualize and we may be able to help.

Essentially, we’re working towards making the concept of industry 4.0 – where you could manage a facility from a desk at home – a (virtual) reality.

Nicolas Vertommen is Marketing Architect of OUAT!