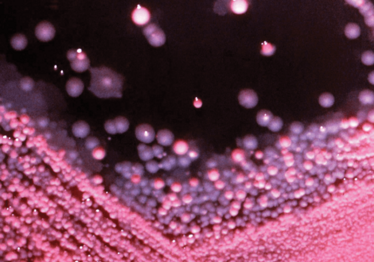

(Anti)Bacterial Factory

Engineered E. coli colonies could be trump cards in the war against drug resistance

Antibiotic resistance has been described as one of the most significant threats facing patient safety. Could E. coli lend a helping hand in the fight? Yes, according to a research team at the University at Buffalo led by Blaine Pfeifer, associate professor of chemical and biological engineering. The team has engineered E. coli to synthesize 42 new forms of the antibiotic erythromycin – three of which have been shown to be effective against bacteria resistant to the version of erythromycin currently used in clinics. And the E. coli factory could be used to produce even more variations. We spoke with Pfeifer to find out more.

How did the work begin?

I was interested in making natural products more accessible by developing alternative production routes. In this case, we were able to produce the antibiotic erythromycin through a heterologous host system and then use the engineering tools of the new platform to produce analogs of the original compound. Production through E. coli provides a maximum operating space that few other production routes can offer.

We look at this as one contribution to the emerging theme of solutions to the antibiotic-resistance crisis. As opposed to ongoing efforts to discover completely new antibiotic compounds, our approach leverages the engineering capabilities of the E. coli platform and the pathway complexity of erythromycin to significantly alter the chemical diversity of an established antibiotic. In other words, our system allows us to engage in a game of molecular chess – a battle between the mechanisms bacteria use to thwart antibiotics and the engineering capabilities we have to produce new compounds.

How does the platform work?

Here, I have to credit the first author of this work, Guojian Zhang (1). He designed 16 pathways for a sugar molecule attached to erythromycin, as a way to systematically vary the molecular content of this moiety. We knew that without glycosylation, the compound does not have any antibiotic activity, so we thought this would be a good place to vary molecular structure and observe new bioactivity. The engineering tools of the E. coli system enabled this design to move quickly, and to our surprise and satisfaction, we were able to generate over 42 new erythromycin compounds due to the variety of steps in the overall pathway. Even more gratifyingly, we observed new bioactivity.

Have you started thinking about scale up?

There is still a series of experiments and tests that must be completed before a final new drug is available. But if those are successful, this system lends itself well to process development given the properties of the E. coli host – a workhorse in the biotech industry.

The analogs produced here are really just a small sub-set of those possible. So, one future direction is to further test the analog-producing limit for the platform we have at hand. There’s also the goal of pushing current and future analogs through the clinical tests needed to result in a new FDA-approved antibiotic. Finally, the approach outlined here could, in theory, be applied to numerous other current antibiotics to produce novel analogs capable of overcoming bacterial resistance.

- G. Zhang et al., “Tailoring Pathway Modularity in the Biosynthesis of Erythromycin Analogs Heterologously Engineered in E. coli,” Science Advances 1 (4), e1500077 (2015).

Making great scientific magazines isn’t just about delivering knowledge and high quality content; it’s also about packaging these in the right words to ensure that someone is truly inspired by a topic. My passion is ensuring that our authors’ expertise is presented as a seamless and enjoyable reading experience, whether in print, in digital or on social media. I’ve spent fourteen years writing and editing features for scientific and manufacturing publications, and in making this content engaging and accessible without sacrificing its scientific integrity. There is nothing better than a magazine with great content that feels great to read.