Breaking the Bioprocessing Bottleneck

Battling logjams in downstream processing is a constant challenge, but even when it feels like there’s no room for maneuver, small yet clever steps can help gain efficiency. And sometimes a fresh pair of eyes can find new and surprising solutions.

sponsored by GE Healthcare

Originally aiming for a career in traditional manufacturing, Madhu Raghunathan obtained an advanced degree in engineering, but later found a passion for the application of innovative technologies. Today, Madhu is Product Strategy Leader at GE Healthcare Life Sciences, where he is tasked with scrutinizing the latest advances in downstream processing operations to help companies identify opportunities for greater efficiency. But the quest for efficient downstream operations is not easy, particularly when you must balance solutions against existing constraints. Fortunately, such problem solving is exactly what Madhu enjoys.

How do you get involved with downstream-processing challenges in your role at GE Healthcare Life Sciences?

My role is to specifically focus on downstream processing. I analyze the market, and study the trends, challenges and constraints facing our customers. From there, I look at how we should evolve our portfolio to ensure that we can address these problems and help make downstream bioprocessing operations more efficient. It’s a fascinating area because the solutions and technology applications vary depending on the situation – there is no ‘one-size-fits-all’ approach. I must look at how innovative technology and a combination of approaches and knowledge can be pieced together to solve real-life problems in a practical way. I’m very interested in process analytical technology, continuous processing, automated unit operations and real-time product release because there are a lot of innovations being seen in those areas. But across the board, whenever GE gets involved with downstream processing, I am happy to join the team to examine areas that can potentially be improved.

Could you provide some examples of technological innovation?

I'm seeing a lot of interest in automating unit operations as recent developments in automation platforms facilitate efficiency and scalability. A lot of companies are also looking at the potential of continuous chromatography and continuous processing; some companies are starting to experiment with continuous chromatography for one purification step, while others are rolling out continuous processing for their entire chromatography operations – or even looking at an end-to-end continuous downstream processing operation. That said, I think that mainstream adoption of these techniques is still a few years away, as they are still novel and the industry is still figuring out how best to implement and use them.

One technology that is becoming more mainstream, however, is single-use systems. Companies are definitely more aware of – and more at ease with – the challenges and benefits of single-use technology. I’ve seen a lot of ‘hybrid’ processing operations that use single-use technology for certain steps, and then traditional stainless steel for other steps, resulting in more economical and functional processes.

What are today’s most common downstream bottlenecks?

Historically, resin capacity constraints and column footprint were perceived as the main bioprocessing bottlenecks, but these aren’t really a problem in today’s industry where binding capacity and downstream productivity tends to be high. This is in part thanks to new developments in downstream processing equipment and materials. However, this doesn’t mean that bottlenecks no longer exist; on the contrary, I believe that most bioprocessing companies today face some form of bottleneck in their production processes. This is especially true for companies that have legacy production facilities.

One common bottleneck is inefficient process handling during scale up, such as moving from pilot- to full-scale manufacturing. Many different steps make up downstream processing and all of these need to be scaled up, which can involve hold times for buffers and necessitate new controls to manage things effectively. In addition, once you start scaling up in volume you start to see increased preparation times and higher footprint requirements. If your processes aren’t efficient, then delays can occur, which can cause buffers to be held for too long or affect time-critical steps.

Another common bottleneck is column packing. While traditional column packing is a very slow and manual process that requires testing activities, it is still used by many companies. Single-use technology is a third potential bottleneck that companies are not always prepared for. The vision behind the technology is that you ‘plug and play’ a new component and then move on with your processing. Single-use technology certainly offers many advantages but the implementation can also include challenges. Such challenges are often related to the infrastructure that is already in place. In addition, single-use technology will require additional qualification activity, such as extractables and leachables studies.

Another common bottleneck is cleaning and its validation, which affects many areas of pharma and biopharma manufacturing (interestingly this bottleneck can be mitigated through strategically employing single-use technologies).

And do you have any solutions?

When it comes to proper buffer preparation and buffer handling, there are a couple of approaches. One effective solution is to formulate your buffer using concentrated stock solutions at the right point just in time – this is known as in-line conditioning and is really helpful in driving down preparation times, as well as the area and volume required for hold vessels. It makes the process of buffer preparation a lot more efficient by diluting concentrated buffers as and when required in the downstream process.

With regards to column packing, technology can lend a helping hand. Pack in and place technology uses nozzles that somewhat automate the column packing process. Or, even better, there are now columns that employ axial compression technology, and columns that utilize intelligent packing methodology to simplify the packing workflow and help prevent column packs from falling outside of specifications on a consistent basis. Companies can also consider utilizing pre-packed, pre-sanitized, and ready to use columns for pilot scale operations or for campaign use as a means of intensifying their purification process. With the right systems and ancillary products, it’s possible to consistently automate most of the operations around column packing.

As for single-use technologies, I recommend that you have an upfront discussion with a vendor to see what can be done to facilitate the implementation. You need to introduce the technology in a way that is comfortable for you – and you’ll also need to ensure that there is a framework in place for submitting a change control notification in a timely manner. I think that users and vendors should share some of the burden when it comes to rolling out single-use technologies. At GE, we have done a lot of work in ensuring security of supply and building knowledge around integrity testing and single-use qualification. This is essential to allow the industry to reap the benefits.

As for cleaning (and validation) bottlenecks, there are several solutions. As mentioned previously, single-use technology is one. Another approach is to design your bio-burden control strategy in a very effective way and to leverage recommendations made by the manufacturers with regards to how you clean and validate your equipment. In this instance, the documentation that you get from equipment vendors is useful.

Do you think there is a solution for every bottleneck?

I’m sure we all wish we had a magic wand that could transform everything to a lean, productive process stream – but transformation is never easy. Sometimes companies fail to address bottlenecks because they are constrained to doing things a certain way. Biopharma is very regulated and many facilities were built up years ago with legacy infrastructure that can make the incorporation of new technology challenging. It’s tricky to balance your constraints with the need to be more efficient, but there are always at least a few steps that you can take.

For example, one area of concern for all companies is resin and slurry wastage. How do you ensure that your resin is effectively transferred from the container into the column – in an aseptic or a near aseptic manner – whilst ensuring minimum or even zero wastage and, at the same time, ensuring that your slurry has been homogenized properly and that the slurry concentration has been measured accurately? There are solutions that help to improve and automate this process to make it more effective – and these solutions can be implemented irrespective of how the facility is set up. As I mentioned earlier, column packing is another common bottleneck and again you can implement new technologies here to bump up efficiency, regardless of facility constraints you may be facing.

There are a wide variety of solutions in the downstream toolbox, from resins, to columns and systems, to consumables – and our toolbox is constantly expanding. When I’m looking at problems, I pick and choose the right tools and solutions depending on the specific situation (and constraints) that I’m dealing with. There is always something. I strongly advise working closely with a vendor because they will have worked on many different projects in many different facilities, which gives them a huge amount of process experience – you may be surprised by the innovative ideas that they can propose.

How can biopharmaceutical companies prepare for future requirements?

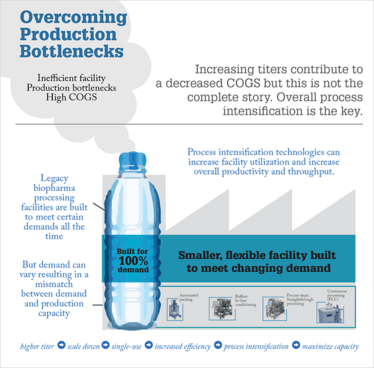

Whenever you are looking to build a new facility or revamp an old one, it is crucial to have a good understanding of not only your current requirements, but your future requirements too. Historically, companies have built a large facility and made a huge investment upfront, with the expectation that the demand would come later. But it could take several years to build up a reliable cash flow, which is clearly not the most effective way of building a business. It is far better and more cost effective to keep capacity in line with demand. By designing a facility to be modular, you can meet current demand and build up when necessary.

Part of my role is to make sure that companies have this in mind and I recommend that you think carefully about the scale of operations, throughput and type of facility infrastructure that you may need in place. Are you going to have a controlled environment? What is grade-space? What are your future expectations? Are you going to manufacture a single drug or are you going to manufacture multiple products? Answers to these questions and others all play a big hand in the way a facility is built up.

Remember that one size does not fit all! Just because something worked in a specific scenario at a specific scale does not mean that it will work work at any scale or in any production paradigm. We must think carefully and make the right choices. After all, selecting the correct solution is a critical factor in making your operations as efficient as possible.