Key Considerations When Partnering with a CDMO for Your Plasma-Derived Therapies

Experts from Emergent BioSolutions break down the qualities that make an ideal CDMO partner for plasma- based protein manufacturing

Jeff Morier, James O’Meara | | 5 min read | Practical

sponsored by Emergent BioSolutions

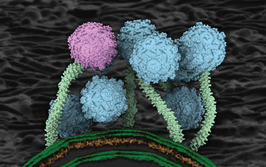

Plasma contains an array of beneficial constituents that, when purified and concentrated, can be administered as medicines to treat rare and complex diseases. The generation of complex plasma proteins is something that animals have developed over the course of evolution. For drug development, skill and expertise is required to isolate these proteins from the blood and purify them into commercially viable and effective concentrations – in a safe, controlled manner that does not damage or destroy their unique structure and properties.

Two particular challenges, however, make plasma protein purification more difficult than manufacturing processes for other types of therapeutics. First, the complex and variable nature of the plasma matrix requires careful consideration during the initial purification step. Plasma contains numerous proteins with very similar physicochemical properties, so a multi-modal approach is required to selectively purify the target molecule.

Second, plasma is derived from natural sources, so the validation of orthogonal virus reduction steps is crucial. Physical segregation of the plasma product throughout the production facility is also required as the product moves from one viral zone to the next to prevent cross contamination.

Ultimately, a well-developed and controlled process is key when working with plasma, but building a strong understanding of the design space and implementing robust process controls requires significant time, energy, and costs. Proteins are highly sensitive to environmental conditions, and even the most subtle of changes may have an amplified effect in a purification process. If a process is not well developed or well understood, these subtle changes can have a negative impact on the product yield and impurity profile.

It is important to employ well-trained, experienced manufacturing personnel who understand the specificity required to selectively purify the target plasma molecules from complex plasma matrixes. It’s also important to know how plasma proteins behave in chromatographic and tangential flow filtration (TFF) steps. Functions supporting manufacturing should also include experts with extensive knowledge of the complexities that surround plasma protein purification.

Key Questions When Selecting a CDMO

- Personnel. Does the CDMO have personnel with experience in the development, manufacture, and testing of plasma products?

- Facility fit. Does the facility have the equipment required to fit the process scale? Can the facility accommodate smaller early phase clinical batches and scale-up to commercial batch size? Does the CDMO have the necessary equipment, people, and systems to meet the intended manufacturing cadence?

- Project management. Does the CDMO have robust and dedicated project management systems that are closely integrated with the tech transfer, manufacturing, analytical, and quality teams?

An experienced CDMO team will help clients navigate the complexities of product development, formulation, assay development and transfer, process tech transfer, scale up, and commercialization. The right partner should also be well positioned to understand a client’s process and product, interpret the facility needs, recommend alternative technologies when required, and demonstrate flexibility in navigating the path to commercial manufacture. A clear line of communication between client and CDMO is also integral to the success of the partnership.

Seeking an external partner

Partnering with a CDMO experienced in this space can help overcome the challenges of working with plasma and provide a more efficient path to clinical and commercial production. Companies with a lab or pilot scale process often lack the facilities or equipment to scale the process to a clinical or commercial level. For a company with products in early phase development, where product success has yet to be determined, investing heavily in capital expenditure to build a manufacturing space, purchase equipment, and recruit the appropriate team members can be risky.

When a client comes to a CDMO to make their product, they can leverage that CDMO’s manufacturing capabilities and personnel expertise, with the expectation that they can deliver a quality product. CDMO’s experienced in plasma protein purification, such as Emergent, already have the infrastructure, personnel, expertise, manufacturing equipment, and other resources in place to support development, tech transfer, scale up, and commercialization. Experienced CDMO’s should also have suppor ting systems, such as expertise in materials management (procurement, shipping, testing, storage of plasma units, and so on), quality, and analytical services – and a robust project management system to ensure everything runs smoothly. A mature quality management system – coupled to a strong quality culture – is also a must.

Emergent’s Center of Excellence for Plasma Proteins

Emergent has the manufacturing capabilities and capacity to support plasma-based products at any stage of development. For those with commercial products on the market, Emergent also offers contingency in terms of manufacturing continuity and to plan for fluctuations in market demand and future market growth.

Our facility in Winnipeg, Canada, is a Center of Excellence for plasma protein purification and has experience with manufacturing products that are approved or licenced in the United States and Canada. In fact, the plant has over three decades of experience in the production, purification, filling, and packaging of commercial plasma-derived products (from both human and animal sources).

We are also very proud of the excellent retention rate of our highly skilled and knowledgeable subject matter experts. The retention of expertise at the Winnipeg site is a testament to the strength of the working culture and a measure of the commitment and dedication to protecting and enhancing lives. This depth of high- quality expertise ensures that Emergent remains well-positioned to support clients in the successful development and execution of their plasma protein related processes.

By developing, manufacturing, and delivering our own well-established IgG products to the market, Emergent is uniquely positioned to support fellow biopharma innovators in successfully bringing plasma-derived therapies from development through tech transfer to commercialization.

Meet the Authors

Jeff Morier:“During my career, I have been fortunate to work on numerous plasma projects. I have seen firsthand the direct link between the work I do and the impact it has on the patient. While each project has common elements, the variable nature of plasma-derived products means that there are always unique challenges to overcome.”

James O’Meara:“My role includes building business relationships with potential clients who are seeking a partner to manufacture their product, from early phase clinical to commercialization. I’m very fortunate to have opportunities to collaborate with various clients and to experience the passion they have for their product – and the patient needs it will meet. Building a manufacturing strategy that delivers a quality product to that client is a very satisfying result.”

Senior Scientist with the Manufacturing Sciences and Technology Group

Director of Manufacturing Operations Projects