Towards Spray Dried RNA Vaccines

Biotech company Ethris explains the benefits and challenges of developing spray dried RNA vaccines.

Stephanie Vine | | 5 min read

Carsten Rudolph

Ethris has recently been awarded $5 million in funding from the Coalition for Epidemic Preparedness Innovations (CEPI) to advance the research and development of spray-dried RNA vaccines that remain stable at room temperature and are suitable for mucosal delivery. Ethris is particularly interested in indications that require delivery to the lungs. Here, mRNA allows for precise control over protein production in lung cells, meaning a therapeutic effect can be achieved quickly and efficiently. We spoke with Carsten Rudolph, Co-founder and Chief Executive Officer of Ethris, to learn more.

First of all, what’s the story behind Ethris?

In the early 2000s, while leading a working group at the Dr. von Hauner Children’s Hospital in Germany, I worked on the development of DNA-based therapeutics for cystic fibrosis. We aimed to deliver plasmid DNA to lung tissue, but a major challenge was delivering the DNA into the nucleus, where transcription into mRNA takes place. This challenge is especially pronounced in post-mitotic lung cells, where the nuclear membrane does not breakdown, posing a significant barrier to DNA entry. This led me to the idea of trying mRNA.

At that time, we already knew that our delivery systems and nanoparticles could effectively transport mRNA into the cytoplasm, where it could be directly translated at the ribosome to produce the missing protein. My ongoing collaboration with Professor Christian Plank, an expert in nucleic acid carrier systems at the Technical University of Munich, further reinforced the significant therapeutic potential of mRNA. Recognizing this opportunity, we combined our research efforts, and Ethris was born.

Tell us about your mRNA technology…

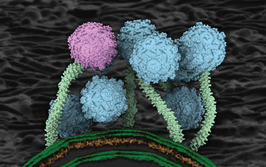

Our technology platforms are designed to overcome key challenges in mRNA therapeutic development – barriers that have historically slowed progress in this field. These challenges include mRNA immunogenicity and instability, storage limitations, and issues related to biodistribution and nebulization, when delivering to the lung. To address the immunogenicity issue, our SNIM (Stabilized Non-Immunogenic) RNA technology is a novel nucleic acid therapy platform that introduces chemical modifications in the RNA molecule to make it unrecognizable but functional to its therapeutic role.

Product stability has also always been at the core of our technology development for mRNA medicines. The mRNA molecule must be delivered into the cell before it breaks down, which we have achieved with a proprietary lipid nanoparticle (LNP) platform technology that enables efficient transport of mRNAs through respiratory and intramuscular routes.

On the other hand, lung delivery involves nebulization of the product, which induces additional stress to the formulation and can lead to aggregation of the LNP. We have developed a stabilizing excipient that can be added to the LNP formulation to fully prevent aggregation. We can vortex our formulation for more than 30 minutes without seeing any aggregation of LNPs.

Another critical challenge of all mRNA medicines is ensuring targeted delivery to respiratory tissues while minimizing systemic exposure. Achieving this delicate balance is essential to prevent unintended effects of the drug on other organs and systems in the body. In our completed Phase I clinical trial we have shown that we can achieve localized expression of the target protein in the nasal epithelium without any relevant spill-over of the mRNA, the proprietary lipioid or the resulting protein.

Finally, storage and supply chain distribution of mRNA -based medicines is a known challenge. Our proprietary lipid formulation has a unique composition and stabilization mix that allows excellent mRNA stability at temperatures ranging from -20°C to room temperature. We have developed lyophilization and rapid rehydration processes, providing product stability for long term storage and distribution at room temperature. In addition, we are currently advancing research to develop spray dried mRNA vaccines that remain stable at room temperature.

What are the benefits of spray dried vaccines?

Spray drying has two main advantages. First, it is the standard technique for inhaled drugs as it allows for easy adjustment of process parameters to achieve the optimal mass median aerodynamic diameter (MMAD) suitable for inhalation. Second, the process is highly scalable and can be run as a continuous process. In contrast, lyophilization is significantly more complex in terms of scaling and integration into your Chemistry, Manufacturing and Controls strategy.

Spray dried vaccines also offer improved patient convenience by enabling patients to carry their drugs while traveling, without the need for a cold chain. Spray dried formulations can be stored at room temperature, which will also facilitate the global distribution of mRNA drugs.

What are the scientific and technical challenges of successfully spray drying RNA?

The biggest challenges in spray-drying RNA arise from several stress factors that affect the formulation during the process. Spray drying induces mechanical stress similar to that of nebulization, which in standard LNP formulations leads to LNP aggregation. Additionally, the drying process of the sprayed particles exposes the formulation to significant heat, which damages most LNP formulations.

Another challenge is minimizing water content to ensure long-term stability of the drug product. Our lyophilized LNP formulations have demonstrated stability at room temperature for more than 18 months. Our spray dried formulation achieves a very comparable water content, and we therefore expect similar stability, but studies are currently ongoing to confirm this.

Nasal administration can be difficult due to nasal anatomy variations and other challenges. Have you already started thinking about the challenges?

One of the biggest challenges of nasal administration is the limited volume that can be administered into the nose compared to inhaled delivery. In our first clinical trial, successfully completed last year, we addressed this issue by using a highly concentrated suspension, achieving protein expression at levels significantly higher than the predicted therapeutic window. The second challenge is ensuring even distribution of LNPs after administration. To tackle this, we are currently working on a spray-dried powder designed for high loading of mRNA and uniform distribution within the nasal cavity.

How did this work attract funding from CEPI?

CEPI is primarily interested in enhancing access to RNA-based vaccines by increasing thermostability, which would facilitate distribution to regions lacking cold-chain infrastructure and offer an alternative for individuals with needle phobia. Additionally, a mucosal vaccine might stimulate a more robust immune response and help reduce pathogen transmission. CEPI recognized Ethris as a leading company in this field, especially after results from our clinical data last year which showed that our formulation is safe, well tolerated and leads to a dose-dependent increase of the desired protein in the nasal cavity.

You recently signed a collaboration with Lonza for the development of spray-dried formulations of mRNA-based vaccine candidates. Tell us more about the collaboration…

The initial focus of the collaboration is to develop a first-in-class mRNA vaccine candidate against influenza delivered nasally. Under the terms of the agreement, Lonza will provide spray-drying and particle engineering for vaccine candidates based on Ethris’ stabilized non-immunogenic mRNA (SNIM RNA) and stabilized LNP platform at its Bend site in the US. Lonza’s support and leading expertise is an asset and provides unique support as we progress development of our mRNA vaccine technology under the CEPI grant. Together, I believe we are well positioned to create promising non-invasive mucosal vaccine candidates that could potentially transform how respiratory diseases are prevented globally.

What else are you working on at the company?

Ethris’ main focus is on the development of treatments for respiratory diseases via nasal and inhaled routes. Our lead phase II ready program, ETH47, is designed to address the upstream trigger of asthma exacerbations and chronic obstructive pulmonary disease, by encoding interferon lambda (IFNλ), a protein essential for viral immunity in the respiratory tract. Approximately 80 percent of acute asthma attacks are associated with virus infections. ETH47 aims to induce a mucosal innate immune response at virus entry sites, as well as inhibit viral replication. Its versatile, virus- and mutation-independent mode of action has the potential to broadly address seasonal and emerging respiratory virus infections. We look forward to advancing ETH47 into phase II trials in 2025.

Our second program, ETH42 to 44, focuses on primary ciliary dyskinesia, a rare genetic disorder caused by structural defects or the absence of cilia lining the respiratory tract, associated with various genetic mutations. This leads to impaired mucus clearance and permanent lung damage. Our products in development aim to address these different genetic mutations by delivering corrected mRNA designed to produce ciliary proteins in the respiratory tract, thereby restoring ciliary function.

Why is the future of mRNA so exciting to you?

I believe we are only at the beginning of an mRNA revolution in respiratory disease treatment. Some companies have already made significant strides by developing in-house technologies that not only enhance the delivery of therapeutic payloads to the lungs but also address key challenges that have historically hindered treatment efficacy.

While there are significant challenges to overcome, the potential benefits are immense, addressing critical unmet needs in respiratory disease treatment. With continued advancements, we can expect to see these medicines become an integral part of the treatment arsenal for respiratory diseases, ultimately redefining the way we approach and manage these conditions. Additionally, with the development of improved mRNA technologies, such as more stable and locally active vaccines, there is significant potential to transform vaccine delivery and accessibility on a global scale.

As pioneers in mRNA for over a decade, we are excited to be part of this ongoing revolution with the potential to reshape the treatment landscape for many diseases. We look forward to sharing progress on our programs – anticipating three clinical read-outs within the next two years – while continuing to build key partnerships for our technology platform.

Making great scientific magazines isn’t just about delivering knowledge and high quality content; it’s also about packaging these in the right words to ensure that someone is truly inspired by a topic. My passion is ensuring that our authors’ expertise is presented as a seamless and enjoyable reading experience, whether in print, in digital or on social media. I’ve spent fourteen years writing and editing features for scientific and manufacturing publications, and in making this content engaging and accessible without sacrificing its scientific integrity. There is nothing better than a magazine with great content that feels great to read.