Nanoformulations: Reach for the (Micro)Sun!

The UK’s Centre for Process Innovation targets easier manufacturing of nanoformulated medicines.

The market for nanoformulated medicines is growing at a significant rate – with an expected value of $350.8 billion by 2025 (1). There is also an abundance of research taking place in the field. Nanomedicines refer to cargos of therapeutics at the nanoscale and may exist as nanoparticles, nanocrystals or other formulations. Manufacturing nanomedicines – and deciding on the best delivery method – is challenging because of the very thing that makes them special: their nanosize. Indeed, significant issues with reproducibility plague nanomedicines, and there have been high failure rates in translating nanomedicines from the bench to the clinic. Today, a growing focus on microfluidics looks to provide enhanced process control and predictability.

Here, we speak with Caroline Kelly, Technology and Innovation Officer at the UK’s Centre for Process Innovation (CPI), to find out how microfluidics and improved process control can give a boost to the future of nanomedicines.

Why has CPI chosen to focus on nanomedicines – and what is “Microsun”?

One important overarching topic at CPI is nanoformulations – and that’s become an even hotter topic given the pharma industry’s interest in nanomedicines. In one nanomaterial project, our scientists are evaluating a new microfluidic-based platform for the scale-up, process development and manufacture of nanoformulated medicines. The aim is to make the platform available for further collaborative R&D or private projects at the CPI’s National Formulation Centre in Sedgefield, County Durham, UK. The project’s name is Microsun.

Who is involved in the project?

The project builds upon expertise and resources currently available within the University of Strathclyde (through Yvonne Perrie) and the University of Manchester (Jayne Lawrence), who have experience in the design of nanoformulations based on lipids and polymers, respectively. We’re also working with AstraZeneca, Pfizer, Croda, Malvern PANalytical, and Precision Nanosystems – whose industry experience and opinions on gaps and hurdles in the field has been invaluable.

Two work-streams will initially run simultaneously across the two universities to evaluate at-line process analytics, in-line tangential flow filtration and determine relevance to the control of product quality. At CPI, we’ll be focusing on supporting the technology transfer of formulation compositions, process design, scale-up and the development of process metrologies to enhance process control.

Why Nanoformulate?

Traditional therapies are limited in the following ways:

- Non-selective: they target healthy cells as well as diseased cells, resulting in toxicity whilst efficacy is poor becausethe quantity of drug at the target site is low.

- Short blood half-life: small molecules and peptides are rapidly metabolized or removed from the body, so large and frequent doses are required to achieve the right amount of drug at the target site (in some cases, this cannot be achieved at all).

- Multidrug resistance: targets can become resistant to the drug, where the drug is removed by/cannot enter target cells.

- Difficulty crossing biological membranes (for example, blood-brain barrier, gut wall, target cell membranes, and so on).

- Poor physicochemical properties; for example, a lack of aqueous solubility or poor stability in the body.

- Small molecule/traditional biologic drugs are not suitable for many biological targets implicated in disease; new types of molecule are required (for example, nucleic acids), but they can be difficult to deliver to target sites and require cellular penetration and trafficking to the appropriate compartment in cells.

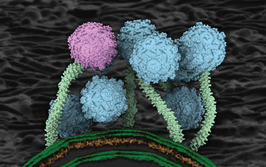

Nanoparticles, on the other hand, encapsulate active pharmaceutical ingredients (APIs) or biological nanostructures, with the following benefits:

- Increased efficacy: more drug delivered to site of action.

- Decreased toxicity: less drug delivered elsewhere in the body, reducing side effects.

- Increased use of chemical space, providing access to a wider range of therapeutic modalities; for example, we can develop drugs that would otherwise be difficult or impossible to move forward.

- Enables evaluation of innovative and emerging therapies with potential to treat underserved diseases; for example, nucleic acids therapies, therapeutic vaccines, gene editing technologies.

Why are microfluidics important for the development of nanoformulations?

Microfluidics help manipulate nanoliter volumes in fluidic channels, making them essential for the scale-up, process development and manufacture of nanoformulated medicines. They can be used for the rapid screening of formulation compositions and process conditions, and to develop the right drug delivery system. Essentially, microfluidics pave the way for reproducible manufacturing to achieve uniform nanoparticle size distributions, which is very important for the efficacy and safety of a nanomedicine. Furthermore, the microfluidic process uses scalable because it is continuous.

Microsun exploits flow chemistry and uses the Nanoassemblr Blaze from Precision Nanoystems. The application of flow chemistry in a microfluidic set-up is advantageous for several reaso

- When small-scale preparations (from milligram to tens of grams) are required – typically in small-volume, high-value business areas – waste products can be minimized and process analytics (in-flow detectors) can be integrated.

- It is typically operator-independent, with computer-controlled variables and easily cleanable/replaceable components.

- You can precisely control the geometry of fluid mixing, thereby allowing accurate control of solvent exchange and the ensuing self-assembly or precipitation phenomena.

- It is possible to run the process across microfluidic chips in parallel to produce the volumes of product required to support clinical development and commercialization – scale-out rather than scale-up.

How is Microsun being used?

We’re using the platform in a number of ‘real-life’ systems. The industry needs more tools for preparing nanoparticles in a more space, time and cost-effective manner. When it comes to increasing capacity and bringing more nanomedicines to market, we need more efficient approaches.

The Microsun project isn’t just about microfluidics. We are also incorporating other advanced systems that can help with nanomedicine development, including technologies for the purification, real-time analysis and testing of finished products, which will be used to develop manufacturing processes for a range of complex nanomedicine technologies. In particular, the ability to monitor the quality of products in real-time, and to adjust the process to deliver in-specification materials, will be critical to the future success of our platform – these are essential attributes for the pharma industry.

Meet CPI

CPI works with business to translate inventions into products and processes that enhance health and well-being, protect and improve our environment and increase productivity across industries. Part of of the UK Government’s High Value Manufacturing Catapult, CPI offers an understanding of innovation processes and financing, combined with industry relevant technical expertise and assets. The centre operates across many markets, including pharmaceuticals, speciality chemicals, food and drink, electronics, and transportation; and aims to help products and processes be quickly and cost-effectively brought to market, supporting the development of next-generation manufacturing. In 2014, CPI was awarded a £28 million grant to establish The National Formulation Centre, which works across a range of key technology areas and market sectors. Part of the grant is being used to develop capabilities for the UK formulation industry that do not currently exist.

What are the next steps?

The project will run for two years and we’ll be aiming to:

- Demonstrate that a range of nanoformulations containing relevant active pharmaceutical ingredients can be developed rapidly using microfluidics.

- Evaluate the benefits of at-line particle size analysis and in-line formulation purification on control of product quality attributes and speed of process development.

- Demonstrate process optimization and scale-up of nanoformulations using parallel processing.

- Demonstrate the successful transfer of scale-up processes into GMP manufacturing facilities.

Collaboration is essential for this project – we need a variety of expertise. It’s important to keep in mind that we all operate at different stages of the innovation cycle. If we talk in general terms around TRL (technology readiness levels), then academia is generally active at the TRL levels 1-3, with industry active across the spectrum. In this regard, multi-national pharmaceutical companies have a much greater focus than ever before on the internalization of novel concepts from the wider science community – and this typically requires external support to help translate early concepts into commercial reality.

The role of organizations like CPI is to help bridge the “valley of death” where many good inventions (by which we mean technically feasible and sought after) are not successfully commercialized. In the Microsun example, CPI is working to de-risk the innovation by providing open access facilities that remove the need for individual companies to invest in their own research infrastructure. Centers like this are also in a good position to collaborate effectively with academia to move new technologies through the TRL levels to make them more interesting and appealing to industry.

- Grand View Research, “Nanomedicine Market Size Worth $350.8 Billion By 2025 | CAGR: 11.2%” (2017). Available at bit.ly/2M0Bwqv. Last accessed August 3, 2018.

Over the course of my Biomedical Sciences degree it dawned on me that my goal of becoming a scientist didn’t quite mesh with my lack of affinity for lab work. Thinking on my decision to pursue biology rather than English at age 15 – despite an aptitude for the latter – I realized that science writing was a way to combine what I loved with what I was good at.

From there I set out to gather as much freelancing experience as I could, spending 2 years developing scientific content for International Innovation, before completing an MSc in Science Communication. After gaining invaluable experience in supporting the communications efforts of CERN and IN-PART, I joined Texere – where I am focused on producing consistently engaging, cutting-edge and innovative content for our specialist audiences around the world.