The Future of Cell and Gene Therapy Purification

| 4 min read

sponsored by Astrea Bioseparations

The challenges of bioseparation are well documented, but cell and gene therapies present even more complications. One company that is working on effective solutions is Astrea Bioseparations (a Biotage company), which specializes in the efficient separation and purification of biopharmaceuticals. Recently, the company expanded its expertise into the advanced medicines space, with new solutions specifically designed for cell and gene therapies. We spoke with Marc Hummersone, Senior R&D Director at Astrea Bioseparations, to learn more.

What’s the story behind Astrea Bioseparations?

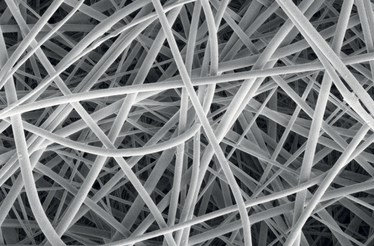

For more than 30 years, Astrea Bioseparations has been at the forefront of adaptable purification solutions, spanning process development to commercialization. Our portfolio is the culmination of cutting-edge chromatography resins and columns, as well as our pioneering chromatography nanofiber material, AstreAdept®. We are committed to advancing the cell and gene markets via products delivered with specialized expertise, innovation, and finesse.

What makes the company’s resins different?

At the core of Astrea Bioseparations is the PuraBead® resin range, which is manufactured via a unique supply chain that starts with the harvesting of seaweed. PuraBead is a testament to our dedication to sustainability and innovation; after all, seaweed cultivation plays a crucial role in absorbing environmental CO2, and enhancing water quality, while contributing to biodiversity and ocean acidification mitigation. Our products avoid microplastics and significantly reduce solvent use, marking a step forward in sustainable bioprocessing.

Following an unprecedented period of growth in the last two years – particularly in the market demand for our PuraBead base resin bead – we have evolved our production process to a semi-continuous operation that ensures around-the-clock productivity. Looking forward, we are excited about the construction of a new bead manufacturing facility on the Isle of Man (part of the British Isles) to cater to the anticipated growth demands of 2024. Our in-house manufacturing strategy guarantees a reliable and speedy supply chain for customers.

What new products has the company recently released?

As the biotherapeutic industry shifts towards more specialized modalities, the need for precise chromatographic processes has never been greater. In response, we've developed the PuraBead Edge – a ground-breaking resin bead designed for superior resolution and enhanced binding capacities. These smaller beads significantly increase dynamic binding capacity and improve resolution – both of which are critical for effective separation. We’ve meticulously balanced these attributes to optimize productivity, addressing potential issues, such as increased back pressure and flow rates, ensuring the 65 μm beads offer optimal balance.

How will your technologies drive change in the cell and gene space?

Cell and gene therapy modalities are magnitudes larger than small molecule or recombinant protein-based therapies – and existing technologies fall short for purifying lentiviral vectors, exosomes, or plasmids. Our commitment to innovation led us to develop AstreAdept technology, which is specifically designed to address the unique challenges of cell and gene therapy, ensuring high productivity for downstream applications.

We’ve tailored our solutions to overcome common obstacles faced by process developers, including yield recovery, scalability, and the inherent fragility of larger modalities. Furthermore, our technology includes low salt elution and axial capsules that scale seamlessly plus a low-shear environment that maximizes recovery.

We believe that AstreAdept is poised to revolutionize the market by enabling clients to expedite their time to clinic and reach patients faster. Our ambition extends to scaling AstreAdept for manufacturing, offering comprehensive support from process development through to commercialization, reinforcing our dedication to innovation and customer success.

Astrea Bioseparations recently invested in a new facility; can you share the strategy for this site?

Our recent acquisition of a new facility in Boston, Massachusetts, signifies a strategic expansion of our manufacturing and warehousing capabilities to meet the growing demands of the North American market. This site will serve as a critical node in our supply network, offering a range of services and support to enhance our operational efficiency and customer service.

The new facility features cleanroom laboratories dedicated to column packing, alongside versatile workspaces for offices, warehousing, and column assembly. This expansion is poised to significantly increase our production capacity for pre-packed column products and services, while also accommodating our extensive range of chromatography technologies, including the AstreAdept nanofiber-based range. We are now in an even better position to support the needs of commercial-scale biologic production.

Purabead and AstreAdept are registered trademarks of Astrea Bioseparations Ltd

Click here to learn more about Astrea Bioseparations