Virtual Facility Design

A facility can be planned on paper, but will it “feel” right and function as expected? Virtual reality can provide a sneak peek into potential problems by allowing you to walk around facilities before they have been built.

It can be disorientating when you first experience VR, since what your eyes are telling you and what your body is doing are out of phase with one another. It does, however, have a definite “wow” effect. VR is a fully immersive experience and I think the potential applications are fascinating. In 2015, at the BioProcess International trade show, we used VR to show visitors how our cell therapy bioreactors worked. However, VR can do far more than draw people to a booth.

The story of how Pall became interested in VR is a winding one. We produce a wide range of content in terms of operator manuals and technical training, and we also produce video training manuals for a lot of our equipment in cases where it is hard to describe what to do, but very easy to show people what to do. We are always looking for new ways to do this. A lot of the training items and videos that we produce are made in our facility in Belgium, and the team there started to tinker with 3D modeling in their spare time. They became very passionate about the potential and eventually some of them left to set up a startup marketing company called OUAT! – and Pall became their first contract. We gave them the remit of showing how our cell therapy bioreactors worked and how they fit into a facility.

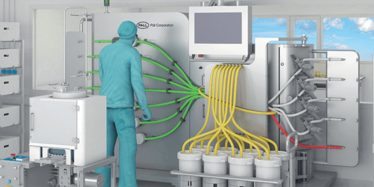

OUAT! created a 3D virtual world that users could interact with. It was early days for VR and to be honest the optics weren’t great, but we presented it at the BioProcess International show anyway – and people loved it. Visitors interested in cell and gene therapy could walk around a virtual facility and look at where the bioreactors were installed and interact with them – albeit in a fairly modest way. Based on the response and feedback from people at the show, we were inspired as to what we could do with VR next. In particular, we wanted to do more than just show people something; we wanted to make it more applicable and personalized so that users could be fully immersed.

We went back to OUAT! and the timing was perfect since OUAT! was designing HakoBio – a process and cleanroom planner. They were able to create a virtual space for users to build a laboratory or a whole facility. Users could set the dimensions and then look at where the doors went, where the windows went, where the utility collections would be housed, as well as where other architectural features might be. The aim was for users to either recreate existing facilities (to evaluate where new technology might be placed) or to create new facilities. OUAT! also created 3D virtual models of a very large selection of our portfolio of products that could be dragged and dropped into their designs. It’s something you can do in a lot of engineering or architectural modeling programs, of course, but VR allows you to switch from a design point of view to a virtual view that you can walk around. It may sound like a gimmick to some, but when you walk around a facility, sometimes things become apparent that you couldn’t see on the plan; for example, a location you thought was appropriate for a piece of equipment might not be right. Building a facility is expensive and you want to get it right – being able to walk around and see how it goes together early on can make a big difference.

At the moment, I consider all of this phase I – I think that VR can be taken a step further so that users can actually interact with objects, such as pushing buttons and opening doors. This may sound futuristic, but the technology is already there in the world of video games. If you are interacting with something in the virtual world then you need some kind of tactile feel, as well as position indicators for hands. We are keeping a close watch on the technology. As well as being used for marketing and facility planning, VR could also be invaluable for training operators in the correct use of equipment. Eventually, I’d love to see the integration of computational fluid dynamics so that users can see the behavior of liquids that are being processed through the system. Eventually, maybe we will be able to look at the microscopic level and visualize what is happening in, for example, the interactions of multiple molecules with chromatography resin. We can already perform static modeling with 3D molecular design software, but being able to watch it will add a new dimension – and could drastically change the field.

Ian Sellick is Director of Marketing at Pall Life Sciences.

Ian Sellick is Director of Marketing at Pall Life Sciences.