De‐Risking the Process of Peptide Manufacture

contributed by Bachem |

De‐Risking the Process of Peptide Manufacture.

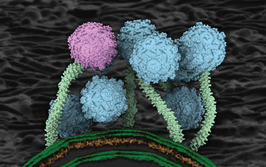

The quality of a material produced by a manufacturing process depends entirely on the process itself, and the robustness built into that process during the development lifecycle. For a number of years, many companies have been looking towards the Quality by Design (QbD) approach to process development to ensure this robustness, and Bachem is no exception. Bachem, the world’s longest established and largest manufacturer of Peptide APIs, prides itself on the quality and consistency of peptide API produced for customers. One of the lynchpins of this success has been derived from FDA guidance on QbD approaches and Quality Risk Management.

The International Committee for Harmonization (ICH) defines QbD as follows:

“A systematic approach to development that begins with predefined objectives and emphasizes product and process understanding and control, based on sound science and quality risk management.”

This provides a framework for us as a contract manufacturer, in collaboration with customers, to gain product and process understanding for the manufacture of Peptide API with clear goals having been defined:

- Gain as deep understanding as possible of the process starting at the earliest possible stage

- Partner with customers at every point during development (intended use drives the quality requirements of the final product)

- Gain full understanding of relationship between every stage of the process and the final product

- Finalize a commercial process delivering the best quality of material for the intended use

Log in or register to read this article in full and gain access to The Medicine Maker’s entire content archive. It’s FREE!