Quantum Leap in Real-time Monitoring?

Continuous monitoring of pharma products with an innovative matchbox-sized laser

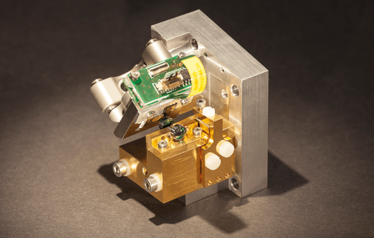

Product quality monitoring is essential in pharma and chemical production, but often performed manually. Researchers from two Fraunhofer Institutes (Applied Solid State Physics in Freiburg and Photonics Microsystems in Dresden, Germany) may have found the ultimate solution. The team has developed a matchbox-sized laser module that can be rapidly tuned over a wide spectral range, opening the door to spectroscopic identification and quantification of substances in real time. For pharma manufacturers, this means the ability to trace chemical reactions or to measure product composition continuously.

“At any time, you’ll know exactly what is happening, such as what and how much substances are currently involved. This means you can continuously monitor the quality check and be aware if something strange happens. You won’t need to take random samples and pass them onto the quality control lab,” says Ralf Ostendorf, project manager at the institute in Freiburg.“We used a small silicon chip that integrates an optical diffraction grating in a micro-optical-electric mechanical system (MOEMS) scanner and combined this with a quantum cascade laser (QCL) chip. Both chips independently measure only a few millimetres – but the potential seemed enormous,” says Ostendorf. The original goal was simply to develop a miniaturized laser source, but the team decided to test the capability of laser-based mid infrared spectroscopy in different applications.“We’re currently working on our first real-time spectroscopic measurements to demonstrate the capabilities of the technology,” says Ostendorf. “The absorption lines of chemical substances are very characteristic and strong in this wavelength range. It’s a really sensitive solution that can detect even small traces of chemicals.”

Ostendorf expects that the system could easily integrated into pharma settings, and believes its tiny form factor could lend itself to a commercial handheld sensor. It’s still early days, but widening the spectral tuning range could open up access to applications outside of pharma and chemical manufacturing. In fact, Ostendorf also has his eye on the clinical sector – perhaps identifying lung disease from breath samples – at which point, the term quantum leap seems entirely justified.

Making great scientific magazines isn’t just about delivering knowledge and high quality content; it’s also about packaging these in the right words to ensure that someone is truly inspired by a topic. My passion is ensuring that our authors’ expertise is presented as a seamless and enjoyable reading experience, whether in print, in digital or on social media. I’ve spent fourteen years writing and editing features for scientific and manufacturing publications, and in making this content engaging and accessible without sacrificing its scientific integrity. There is nothing better than a magazine with great content that feels great to read.